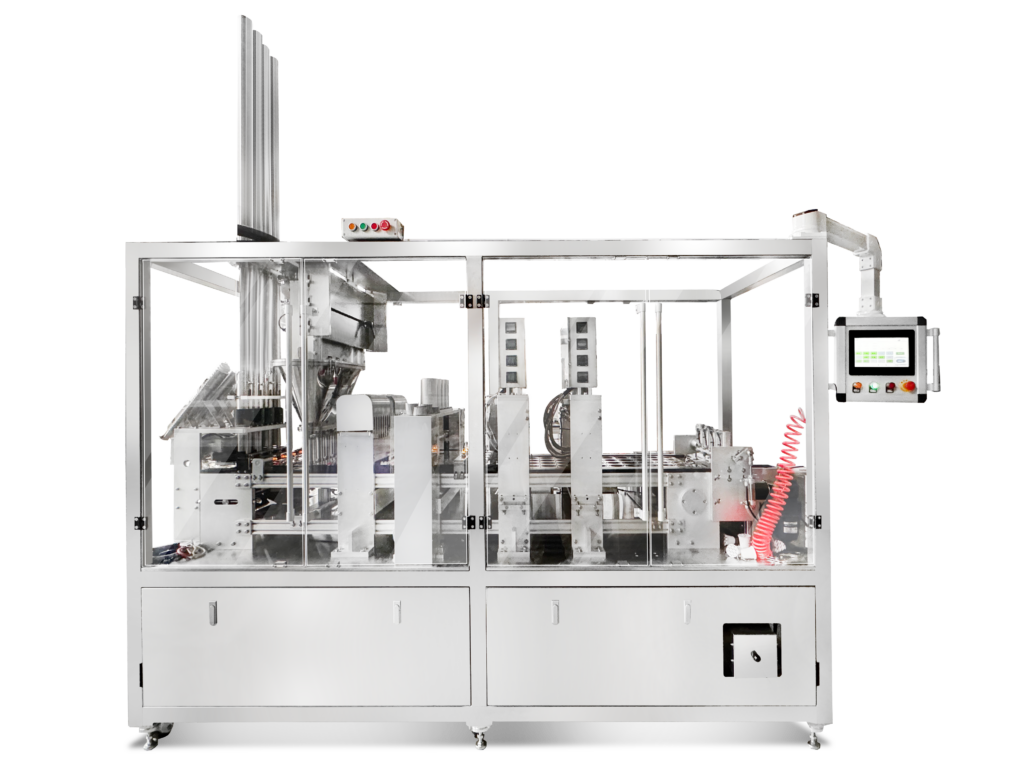

AF-B10 K cup packaging machine is the quality solution to pack the 10/20/30 Kcups into boxes and produce the beautiful box package, reduce the labor cost.

The machine adopts the latest technology. According to market feedback, we continue to optimize the structure of the machine. Now our B10 k cup packaging machine can realize functions such as precise cup counting, boxing, etc.

We customize our equipment strictly according to your requirements, so you need to inform us of the size of your carton, the arrangement of K cups in the box, and the type of box, which is better for us to manufacture your K cup packaging machine Play a vital role

This machine meets all the needs of Kcup secondary packaging, you can use the folding box, also can use hot glue sealing box. You can package your Kcup in machines in 5 * 2,5 * 2 * 2, or Random Order, we will have all solutions for you.

All of our K cup packaging machines use food-grade components and do not have high requirements for the production environment.

A large number of mechanized devices are used to reduce the failure rate of the machine.

The maintenance is simple and the novice can easily use it.

AFPAK has a wealth of equipment customization experience, we can personalized design and manufacture of equipment you are satisfied.

Let us know your detailed requirement, we will offer you the complete solutions.

SPECIFICATIONS

| Model | AF-B10 |

| Box package range | min 60x60x60 mmmax 250x170x90mm |

| Package quantity | Customized according to your requirement |

| Machine speed | 30-50 boxes per min |

| Voltage | 220V/60HZ/3PH |

| Machine size | 4800*1200*12000mm |

| Machine weight | 2500KGS |

| Note | This is a custom-build machine, so each machine specifications will have different |

FEATURES

- Adopt PLC and HMI touchscreen automatic control operating system, step-less speed regulation, the high level of automation, easy operation.

- Adopt the international famous brand electric component, the performance is stable and reliable.

- Adopt the Automatic Stop function of mechanical overload to ensure man-machine safety.

- With fault display, alarm, and finished goods counting functions, easy to maintain and deal with the fault.

- According to customer requirements to design a variety of automatic feeder and conveying machines and other devices

- Rugged constructed to guarantee a long service life. Most of the body is built with stainless steel 304 and food-grade stainless steel (SS304) is used for all parts in contact with products.

- Can Be used with aluminum-plastic packaging machine, pillow packaging machine, filling machine, soap making machine, Spray Code Machine (or Regulatory Code System), labeling machine, on-line weighing instrument, three-dimensional packaging machine, shrink packaging machine, belt baling machine, other production lines, etc…

FUNCTIONS

☆ Automatic Sort and feed the empty Nespresso capsules

☆ Automatic detect whether capsules well loaded on the machine by sensor.

☆ Servo motor to fill coffee while vibrating, weight around 5-7g ( can be adjust)(Nitrogen flushing here)

☆ Clean the capsule edge and press the coffee tightly

☆ Put pre-cut lids (can also use rolled film) (Nitrogen flushing here)

☆ Output to the conveyor

☆ Output the finished capsules

OPTIONAL FUNCTIONS

☆ robot hands, we use Yamaha robot hand

☆ auto case packaging machine

☆ Inkjet printer

☆ hot melt glue melting machine

☆ K cup filling sealing machine

SAMPLES MADE BY THIS MACHINE

Machine Pictures