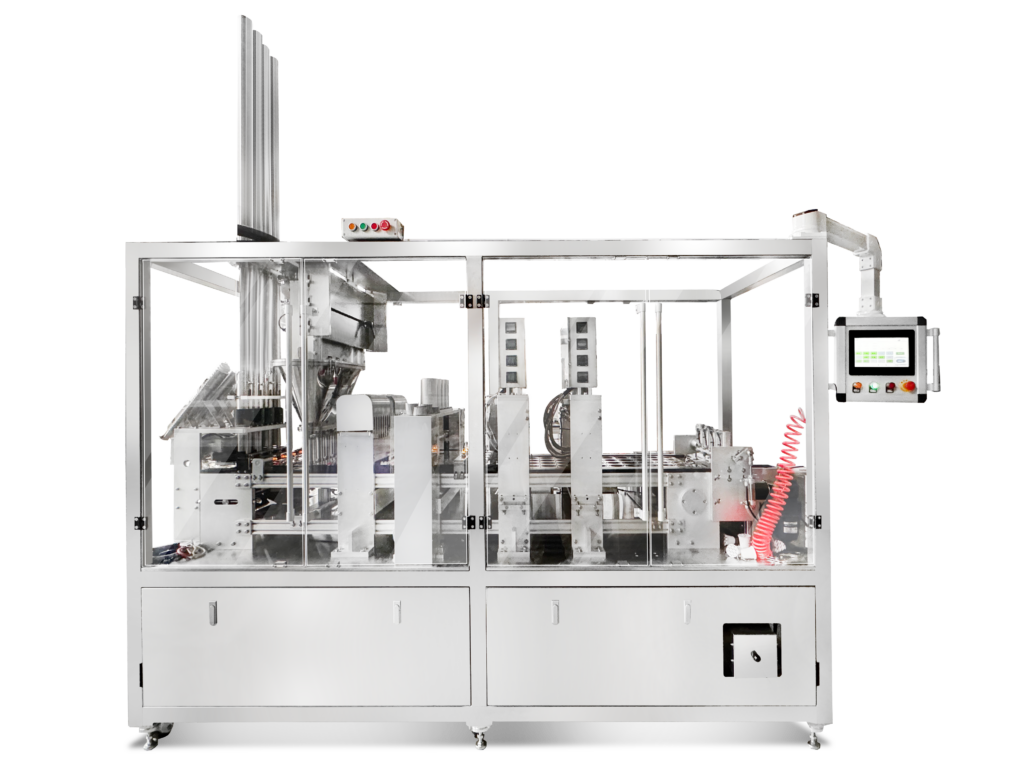

The New Coffee Pod Packaging Machine Arrival!

AF-H4 coffee pods filling sealing packaging machine is a fully automatic coffee pods production line,

We integrate decades of experience and carefully build and upgrade on existing mature machines.

It can help you save more production space and produce more products with less labor.

It is fully functional and can be filled, sealed, filled with nitrogen, and packed into boxes with this production line.

Its high-speed and stable production allows you to better improve the efficiency of the factory

A multi-purpose machine, it can not only pack coffee, but also help you pack instant powder, cocoa powder, tea granules, and other powder and granular products

It has a solid structure, sturdy body, sturdy structure, high-quality accessories, electronic components of well-known brands so that you can use it for a longer time

For your safety, we have many installation devices on our machines, and all of our equipment have passed CE certification

This coffee pod packaging machine can be deeply customized to produce and package coffee capsules such as Nespresso, K cups, Dolce Gusto, Lavazza blue, Lavazza espresso point, etc.

400 Capsules per minute

50 Sq meter space required

1-2 Operator is enough

CE Safety certificated

Coffee Pod Packaging Machine Specifications

| Model | AF-HB410 |

|---|---|

| Package format | 5*2 or 10*1 or randomly dropped boxes. |

| Machine speed | Up to 40 boxes per minute (or 400 capsules per minute) |

| Voltage | Three phases. 220V, 50/60hz |

| Power Consumption | 30A, 20Kw/h |

| Air comsumption | 45 scfm |

| Nitrogen consumption | 30 scfm |

| Machine size | AF-H4: 4800*1000*2300mm; AF-B10: 3500*1500*1650mm |

| Machine weight | AF-H4: 11500KGS, AF-B10: 1000KGS |

| Filling/Sealing heads | 2/4/8 filling heads |

| Note | Please contact us to get more informations |

Too many sales, but limited production capacity and frequent production equipment failures?

AFPAK’s Coffee pod packaging machine solve your troubles

- 10 inches Touchscreen to control

- Two press to run the machine

- Easy to Clean and maintain

The operation interface uses Schneider or Omron brand high-definition 10-inch touch screen, both Chinese and English systems, allowing you to operate handier. (The system can also be translated into your language)

Simplify the operation process: turn on the machine, press the drop cup button, the machine can start production

The material contact parts are made of food-grade 304 stainless steel, and the quick-connect joint is used to link each structure, which is convenient for disassembly and cleaning

The whole machine is made of stainless steel and rust-proof iron, no special maintenance is required

The machine comes with rollers for easy movement

Without too much production space and without paying special attention to the workshop environment, the machine can be well adapted to your factory

The machine is highly automated and can be operated and produced by one person

Excellent performance, stable and efficient

Schneider’s PLC, HMI, servo motor, relay, etc. are used in your coffee pod packaging machine to ensure your production safety. The use of the newly upgraded functions allows the machine to produce longer-term and stable production.

We make every effort to make your equipment easier and safer to use.

Rich and comprehensive functions enable you to better respond to order production

Are you also worried about the lack of productive functions?

Are you worried that the production line is not easy to maintain?

Are you worried about the messy and complicated connection of the production line?

Are you worried that the equipment will often break down and affect production?

Are you worried that no one can be found after the sale of the coffee pod packaging machine, and no replacement parts for the machine?

Come find your coffee pod filling, sealing and packaging solution step by step now.

Large capacity cup storage space, high-speed cup drop

We specially designed a new cup storage mechanism for you, allowing you to place up to 500 empty cups at a time, reducing your frequency of adding cups

The cup drop is customized according to your cup, each manufacturer’s cup has a slight difference, so we are based on the samples you provide.

When the cup is dropped, there will be a suction cup to suck the cup body to ensure that the cup falls into the mold smoothly

500 Capsules straoge volume at least

Servo motor to drop the cups

No Cup, No Fill

Intelligent sensor head to detect whether there is a cup in the mold. If there is no cup, the filling mechanism will not work. After three consecutive vacancies are detected, the machine will automatically stop and alarm.

Smart control the machine running

Omron brand sensors

Each of your coffee capsules is the same weight

Your powders/granules are filled with the vertical screw, and the servo motor controls the operation of the screw. He can quickly and accurately control the filling volume. At the same time, coffee pod packaging machine can also replace parts to produce other powder products.

All food contact parts are made of food-grade materials to ensure your food safety. There is also a nitrogen filling system inside the barrel to keep your coffee freshest

Can be equipped with static eliminator to eliminate static electricity in the powder and make the filling cleaner

0.2 grams filling accuracy

Schneider Servo motor

changeable to produce different products.

Only clean edges of the capsule can have better sealing

Although the filling head has penetrated into the cup for filling during the machine filling, so as to ensure that the cup can enter the coffee cup without spilling, we still help you to add a device for cleaning the residual powder on the edge of the cup Can also tamp the coffee powder in the cup.

Pre-cut aluminum sealing lids Pick and Place

The lids storage cabin can Store at least 1000 pcs pre-cut lids for each lane

You can also use roll film, we will make the roll film cutting and sealing stations for you

The lids cabin can be easily removed to add the new lids.

Pre-cut-lids-pick-and-place.

Pre-cut aluminum sealing lids Pick and Place

The lids storage cabin can Store at least 1000 pcs pre-cut lids for each lane

You can also use roll film, we will make the roll film cutting and sealing stations for you

The lids cabin can be easily removed to add the new lids.

No Lids, No Seal, Machine Stop and Alarm

No film shutdown to better protect the sealing head, and also remind operators to add film in time

Stand out your coffee capsule

The quality and beauty of the seal directly set off the quality of the coffee capsule. If the sealing quality is not high and the sealing surface is not beautiful, your high-quality coffee will be greatly discounted

Our sealing system is composed of a heat sealing head, electric heating tube, electric thermocouple, head bracket, etc. It has a large pressure cylinder and a spring so that the heat sealing head can evenly contact the surface of the coffee capsule, allowing coffee at every angle Capsules can be tight

400 centi degree adjustable

Copper sealing head for better heat conduction

Simple replacement of bad parts

The filled and sealed capsules pick and send to the conveyor

In order to better prepare for the cartoning machine, we have specially equipped the cup twisted function so that the capsules can be connected to the cartoning machine through the conveyor belt in an orderly manner.

Split the capsules to two lanes on the conveyor

According to the requirements of the cartoning machine, we need to divide the cups into two rows, and divided into 5 cups in a row

You can also make other arrangements according to your needs.

Robot hand to push the 5*2 capsules into the tray

Yamaha Robot hand to guide the 5*2 capsules into the box tray.

You can also make other arrangements according to your needs.

Open the box and push the capsules inside the capsules.

The box storage cabin can store more than 200 empty boxes.

The mechanical hand will push the boxes into boxes.

Open the box and push the capsules inside the capsules.

The box storage cabin can store more than 200 empty boxes.

The mechanical hand will push the boxes into boxes.

Hot melt to seal the boxes.

Close the boxes with hot melt glue, strong sealing

The hot melt glue machine we equip the Meler brand, and you can also use yours.

Your satisfaction is our success

Good equipment and good after-sales service

now buy our Coffee pod packaging machine, you will enjoy:

2 years warranty

Lifelong maintenance service

On site installation and Train

7*16 Voice and Video Call

For details, please contact our after-sales staff about all services of this coffee pod packaging machine.