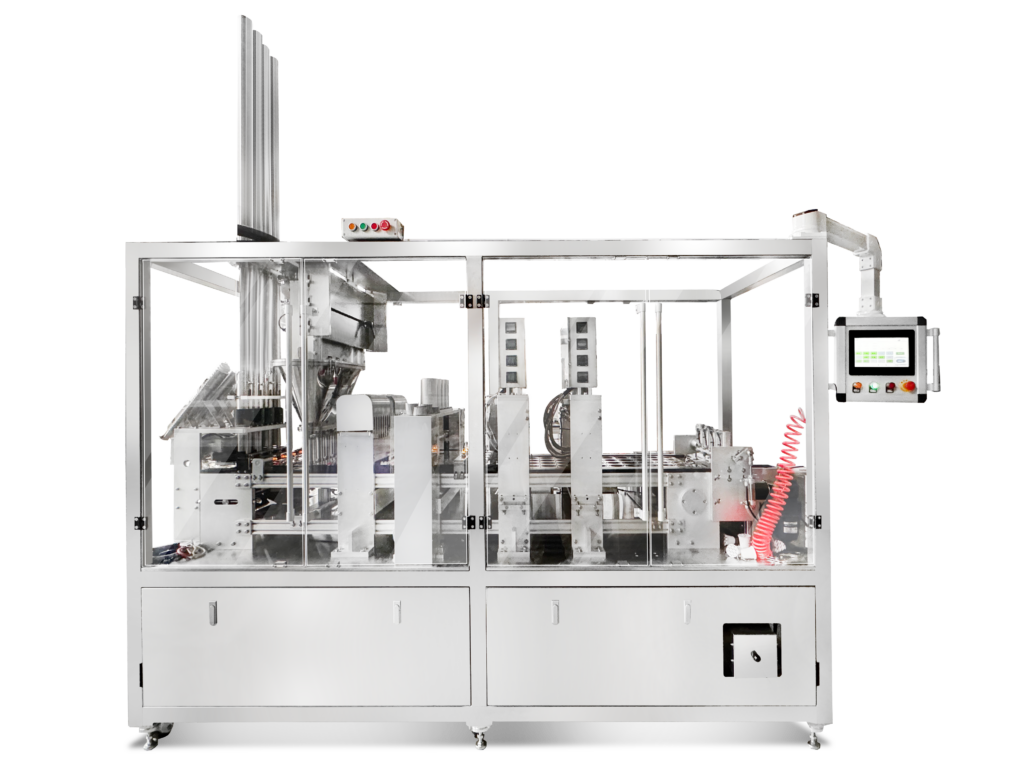

AF-B10 Dolce Gusto Cartoner Packaging machine suits to pack coffee capsules like Dolce Gusto, Nespresso, k cups, lavazza capsules, caffitaly, etc, into boxes with count functions.

The equipment has a wide range of uses, also suitable for car bulbs, LED bulbs, switch sockets, filters, bulk snacks, 502 glue, oral liquid without support, lined cosmetics, pharmaceutical industry, food industry, cosmetics industry, electronic industry paper Box vertical automatic forming packaging.

SPECIFICATIONS

| Model No. | AF-B10 |

| Production speed: | 20-50 boxes per min |

| Paper box’s largest size | 230 x 120x 120mm(can be customized) |

| Paper box’s smallest size | 60 x 20 x 20 mm(can be customized) |

| Paper quality of carton | 250-350g/m3 |

| Motor horsepower | 1.5KW/H |

| Power supply | 220V 50/60HZ single phase |

| Machine noise | ≤80dB |

| Gas source | 0.5-0.8 Mpa |

| Compress air consumption | 260L/min |

| Machine measurement: | L 1100 x W 1500 x H 1700 mm |

| Machine weight | 450Kg |

FEATURES

- It is specially designed to pack small quantities of multi-size boxes.

- With low cost and only require small area. It is suitable for various sizes of boxes. The machine is a vertical type with multiple functions and requires a short time to change mold.

- 304 stainless steel case

- Advanced PLC Control System Combined with a 5.7” Colorful Touch Screen Control Panel, can easily set and change the packing parameters.

FUNCTIONS

Packing Process:

- Push box into star wheel.

- Fold box lower small flap.

- Press both lower big flaps.

- Flatten both big flaps.

- Product fall into box.

- Fold box upper small flap.

- Press both upper big flaps.

- Flatten both big flaps.

- Product push out.

You can also use hot melt glue to close the boxes

SAMPLES MADE BY THIS MACHINE