Coffee Pod Packaging Machine: The Ultimate FAQ Guide

I know you want to learn more about components, working principles, features, specifications, benefits or any other information about coffee pod packaging machines.

So, let’s dive right in.

1. Why Should You Buy Coffee Pod Packaging Machine?

There are a number of benefits of a coffee pod packaging machine that will boost your business including:

High Production

You will experience increased yield since the coffee pod packing machines have varying packaging rates. Compared to semi-automatic versions, fully automated machines exhibit a higher production rate.

Lower Operational Costs

Despite the high initial cost, the coffee pod packaging machine will help you save a lot on the costs of operation.

Superior Coffee Pods

The equipment enables you to develop coffee pods of exceptional quality.

Figure 1 Coffee Pod Packing Machine

Multifunctional

The coffee pod packing machine can perform several other tasks in addition to the packaging coffee. You can use the equipment to clean and package other products different from coffee.

Easy Operation

Since most are automatic, it is very easy to use a coffee pod packing machine. You are required to only load the needed ingredient and key in the necessary parameter and then let the machine run.

Versatile

You can make adjustments to the machine to make different kinds of coffee packages, which have varying sizes and packaging capabilities.

Time-Saving

You will save much of your valuable time when you invest in the automatic coffee pod packaging machine. Moreover, you will need less manpower, which ultimately helps in cutting costs.

Improved Hygiene

The coffee pod packaging machine body design is made of long-lasting stainless steel that is easy to clean. Furthermore, the equipment ensures minimal contact between the operator and products, thus minimizing the chances of product contamination.

Easy Maintenance

The coffee pod packaging machine requires simple and affordable maintenance, which helps in reducing your operating costs. Simply ensure to clean and grease the moving parts frequently.

Enhanced Safety

The coffee processing machines feature sensors that help in minimizing leakages and risks.

2. What Are The Uses Of the Coffee Pod Packaging Machine?

Coffee needs to be packaged in a secure package due to its sensitivity, as it can lose taste when exposed to air and light.

Accordingly, a coffee pod packing machine is essential in creating pods and sealing the coffee powder in them.

In addition to packing coffee, you can use the coffee pod packing equipment for other applications that include:

- The machine can package other products like tea powder, medicine, food powder, and chemicals.

- A coffee pod packaging machine can measure the quantity of coffee prior to filling the pods.

- The equipment has the ability to form the coffee pod shape.

- Moreover, most coffee pod packaging machines can seal and heat print labels on the pods

3. Which Are The Coffee Pod Packaging Machines Types Present In The Market?

Let’s discuss the two main coffee pod packaging machine types that you can select from that include:

Automated Coffee Pod Packaging Machine

This coffee pod packing machine version is fully automated which reduces the number of individuals required to operate it. The machine features a digital control panel where you input most of the settings.

With an automatic coffee pod packing machine, you can perform the following tasks effortlessly:

- Creating the coffee pods

- Measuring the correct coffee amount to use for filling the pods

- Filling coffee into the pods

- Sealing of coffee pods

- Sizing the coffee pods into desired package size

Figure 2 Fully-Automated Coffee Pod Packing Machine

Semi-automated Coffee Pod Packaging Machine

Different from the automatic type, the semi-automatic type of coffee pod packing machine requires human involvement at some point during its operation. However, the involvement of the operator will differ based on the kind of semi-automatic coffee pod packaging equipment you buy.

The machine is less costly but slower compared to the automatic type. Also, you will be required to hire more operators when working with semi-automatic coffee pod packing machines.

4. What Are The Basic Coffee Pod Packaging Machine Parts?

Coffee pod filling and sealing equipment comprise the following main components:

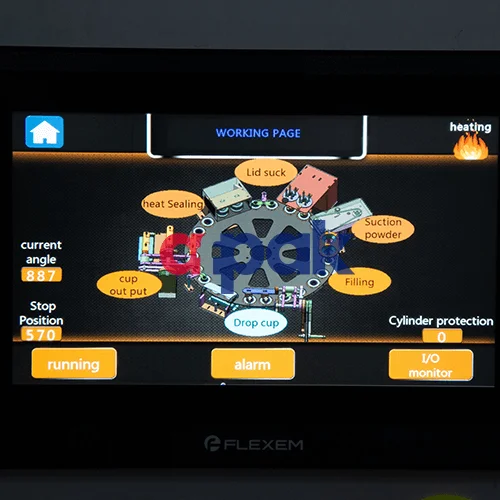

Control Panel

This part comprises of Human-machine interface (HMI) and programmable logic controller (PLC). The control panel allows you to effortlessly key in the production parameters and monitor the system.

Power Control

It is from this part that you switch the coffee pod packaging machine on or off.

Relay

Relays refer to switches that electromechanically or electronically open and close circuitries. They are the parts that regulate the electrical circuitry.

Temperature Controller

The coffee pod packaging machine features a temperature control system that is instrumental in controlling temperature during coffee pods formation.

Eye Mark Sensor

This refers to a tiny, rectangular print region close to the pod packaging material edge. After reading the eye mark, the sensor then:

- Spots the packaging material

- Controls the material position

- Synchronize the splitting and cutting of packaging materials

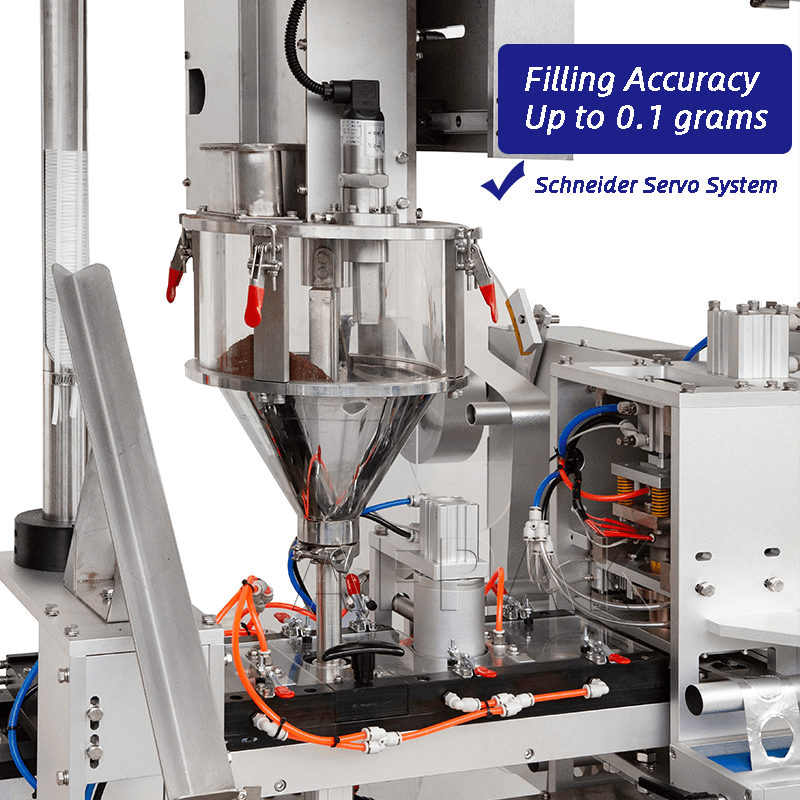

Servo Motor

This comprises a rotary or linear actuator that facilitates controlling of linear or angular positioning. The servo motor is also essential in the speed and acceleration of the coffee pod packing machine.

Coffee Hopper

This is the part of coffee pod packaging machine that carries the raw material you want to pack. It is uniquely sealed to prevent spillage of the hopper.

Moreover, the inner wall of the hopper has a surface treatment that prevents abrasion.

Nozzles And Funnels

The nozzles and funnels direct the products into the coffee pods to inhibit excessive spillage.

Oscillating Tray Dispenser

This part helps in dispensing overly conveyable coffee powders or coffee granules into the pods.

Multitrack Auger Dispenser

The multitrack auger dispenser features a valve that opens and closes to facilitate filling of coffee powder into the pods.

Load Cell

The load cell makes sure that each coffee pod contains the correct amount of coffee after filling.

Pod Denesting Station

Here is where the equipment creates the pods that are used for packaging the coffee.

Conveyor Belt

This is a conveying system that aids in delivering the packed coffee pods.

Tear Notch Sealer

This is the part of the coffee pod packaging machine that seals the pods after packaging. The tear notch sealer makes a tight though easy to open seal.

5. What Is The Working Principle Of a paper Coffee Pod Packing Machine?

The working principle of the coffee pod packaging machine involves the following stages:

Step 1: Preparation

The initial step involves ensuring that the equipment is in perfect working condition. Make sure that all components have no flaws and function as required.

Furthermore, it is in this stage that you prepare all the necessary raw materials, and put the packaging material in correct position.

Step 2: Feeding Raw Material Into The Coffee Hopper

Here, you feed the coffee into the hopper after mixing it thoroughly. Subsequently, turn on the unit and enter the packing parameters.

You input the parameters, such as rate of packaging, coffee pod size, and coffee pod quantity from the control panel.

Step 3: Pod Formation

The formation of coffee pods by the coffee pod packing machine will depend on the production parameters. Utilizing the filter paper, the filter forming system of the machine cuts and develops discs.

Subsequently, the discs formed move to the sealing are where they are sealed to make the coffee pods.

Figure 3 Coffee Pods

Step 4: Coffee Filling

In this stage, the coffee flows from the hopper into auger fillers, which in turn injects the coffee into the pods.

The coffee pod packaging machine automates the changeover of nozzles and funnels in the filling operation.

Step 5: Weighing

The filled coffee pods then move to the load cell, where they are weighed to make sure they are of the required quantity.

You can make the necessary adjustments from the control panel in case the weight varies too much. You do this by changing the feeding variables of the coffee pod packing machine.

Step 6: Cleaning

A vacuum system helps in cleaning coffee that may have spilled on the lids in course of the filling procedure. It is important to clean so as to avoid poor seals, which may result in leakages.

Step 7: Lidding

The machine places lids on the pods and consequently heat seals them.

Step 8: Inspection

The coffee pod packaging machine has sensors that help in inspecting the filled pods to make they are produced and filled properly.

Coffee pods which meet the stipulated standards advance to the next manufacturing stage.

However, if the pods fail to meet the requirements, the coffee pod packaging machine rejects them. This ensures that only high-quality coffee pods proceed to the succeeding process.

6. Can Coffee Pod Packaging Machine Create All Kinds Pods?

Yes, it is possible to develop the two major kinds of coffee pods. You can make these common pod types using coffee pod packaging machine:

- Hard Pods

- Soft Sods

7. What Are The Major Considerations To Take Into Account During Selection Of Coffee Pod Packaging Machine?

Apart from the technical specifications of the coffee pod packaging machine, here are the main factors to consider during selection:

Production Capacity

The production capacity of the machine should meet your requirements. The critical information that you should factor in include filling rate, packaging capacity and rate.

Machine Condition

You should go for a brand-new coffee pod packaging machine that is in perfect working condition.

The relatively low cost of second machines can be tempting. However, it can turn to be costly in the long run due to maintenance costs.

Cost

The price of the equipment differs depending on the supplier. Therefore, it is recommended to inquire with different suppliers in order to do price comparison.

Furthermore, machines with the best specifications will cost more since they offer more in terms of performance.

Type Of Machine

You can either order for semi-automatic or automatic coffee pod packing machine. The level of automation influences the price, with automatic versions being costlier.

Furthermore, the level of automation will also determine the number of operators needed. Semi-automatic types will need more operators, which results in extra cost.

Material Type

You should consider the material for the body and contact parts of the coffee pod packaging machine. Most food processing machines are made using stainless steel because it is sturdy and easy to clean.

Power Consumption And Requirement

The machine should be capable to function with single-phase power supply. Otherwise, you will need to ask for the coffee pod packaging machine to undergo a power configuration.

Air Consumption Rate

Knowing the air consumption rate of the coffee pod packaging machine is crucial in preventing complication during operation.

Dimensions

The coffee pod packaging machine size is determined by its dimensions, which also dictates the weight.

Space Requirement

Knowing the space needed for installation and operation of the machine helps in proper planning of your facility space.

Warranty

Make sure to check the terms of warranty keenly before ordering a coffee pod packing machine from selected manufacturer.

Choose an equipment with a longer warranty period and know the parts that are covered and not covered by the warranty.

After Sale Service

You are advised to settle on a supplier who offers installation and training services. Most reputable manufacturers provide free installation, even though they will do onsite training at a fee.

8. How Does Coffee Capsule Filling Machine Vs. Coffee Pod Packaging Machines Compare?

The two coffee processing machines differ in terms of function.

The basic role of coffee pod packing unit is to create and fill pods with coffee product. Contrastingly, coffee capsule filling machine produces coffee capsules.

Moreover, coffee pod packaging machine utilizes soft materials to create the packaging pods. Contrarily, you utilize plastic/aluminum for packaging with coffee capsule filling machine.

Figure 4 Automatic Coffee Capsule Filling and Sealing Machine

9. What Factors Determine The Cost Of Coffee Pod Packaging Machine?

Some of the factors that determine the cost of coffee pod packaging machine include:

Level Of Automation

The price of fully-automated coffee pod packaging machine is higher in comparison to that of semi-automatic type.

Production Capacity

The production capacity varies with the type and design of machine your purchase. You will pay more for equipment with a higher rate of production.

Machine Size

Typically, machines of large size will be costlier compared to smaller ones.

Features

A coffee pod packaging machine with various special features will be more expensive in comparison to one with basic features.

Quantity

You will enjoy big discounts if you buy coffee pod packaging machines in large scale.

Brand Of Machine

In most cases, reputable machine brands will cost more as compared to little known versions. However, this does not mean that they are of the best quality.

The little known or new brands can be similar or way better than the known brands in terms of performance.

For that matter, always pay more attention of the specifications of coffee pod packaging machine.

Country Of Origin

If you want to save big on cost, source your coffee processing machine from China.

China manufacturers offer better prices compared to others manufacturers around the world.

That said, the price of coffee pod packaging machine may span from US Dollars 500 to 70,000.

10. Which Are The Disadvantages Of Coffee Pod Packing Machine That You Need To Anticipate?

Some of the disadvantages of coffee pod packaging machine include:

Buying Price

Purchasing and installing the equipment is very expensive, which implies you will need to spend large amount of money.

Floor Space

Due to large size of the machine, you will need big space for installing and operating the coffee pod packing machine.

Coffee Freshness

The freshness of the coffee pods may deteriorate if they stay on the shelf over an extended period.

Brew Setting

You cannot employ another brew setting since it is the manufacturer who determines the coffee pods’ brew setting.

11. What Are The Ways of Troubleshooting Coffee Pod Packaging Machine?

Here is how you can solve the common problems during operation of coffee pod packaging machine:

Figure 5 Fully Automatic Coffee pod Filling Machine

The Machine Fails To Power On

Possible causes:

- Incoming power problems

- Main disconnect is switched off

The Machine Fails To Reset

Possible causes:

- Faulty wiring

- Safety circuitry not reset

- Guard doors open

- Low air pressure

- Bad safety relay

- Emergency Stop

Low Air Pressure

Possible causes:

- Machine not reset

- Safety circuitry not reset

- Low incoming air pressure

- Low air pressure in run mode

- Very small supply airline

The Temperature Is Not Within Range

This implies that the set temperature is not corresponding to real temperature.

In such a scenario, you need to inspect all connections and wiring utilizing electrical prints.

Furthermore, also confirm if the solid-state light is lighting up.

Possible causes:

- PLC fault

- Sealing jaws not warmed up enough

- Heater fault

- Temperature sensor fault

- Faulty breakers or fuses

Filter Is Not Tracking Well

This implies that the coffee pod forming material is not moving across the coffee pod packaging machine correctly. First, confirm to ensure that the filter paper carried moves smoothly.

Also inspect all relays, wiring, and power to the servo motor, and clean the brake roller.

Printer Is Not Working

Possible causes:

- Printer is not powered on

- Printer is not set to run

- Printer cable is disconnected or damaged

- Printer ribbon is split

- Printer Is Damaged

With an appropriate preventive maintenance plan, coffee pod packaging machine troubleshooting needs to be uncommon and easy.

12. Can Coffee Pod Packaging Machine Print?

Yes, coffee pod packaging machine have printer that enables you to print your logo, label and other information relevant to the coffee pods.

13. Can You Integrate Coffee Pod Packaging Machine With Existing Coffee Production Line?

Yes, it is possible to integrate coffee pod packaging machine in an existing production line. You can connect the machine to a downstream packaging machine for final packaging.

14. What Are The Crucial Specifications Of Coffee Pod Packaging Machine?

The key specification of an automatic coffee pod packaging machine to consider during purchase include:

- Input Power

- Total Voltage Supply

- Packing Speed

- Air Consumption

- Air pressure

- Machine Dimension

- Packaging Dimension

15. Which Quality Standards Should Coffee Pod Packaging Machine Comply With?

There are several quality standards that the machine should comply with, and often rely on the target market.

Nevertheless, the most popular ones that apply in different markets worldwide comprise of the following:

- CE certification

- ANSI Standard

- ASTM Standard

- Restriction of Hazardous Substances Directive (RoHS) Standard

- cGMP Standard

- FDA Standard

- ISO Standard

For all your coffee pod packaging machines, contact us now.