Coffee Capsule Production Line FAQ Guide

1. What’s the coffee capsule production line machine used for?

It’s used for filling and packing powder products like coffee granules, tea powder, cocoa powder and other granules or powders into single-serve pods like K-cup, Nespresso, Dolce Gusto, Lavazza coffee capsules

The coffee capsule production line machine can assist you in filling and sealing capsules, forming the shape of the coffee pod outer packing.

When put into a coffee capsule production line machine with ground coffee (or other powders) and empty capsules(aluminum, plastic, bio-degradable materials, etc.), you get well filled & sealed & cartoned capsules.

2. What’s the difference between all the coffee capsule production line machines?

The coffee capsule production line machines are mainly differs in size, type, and production output.

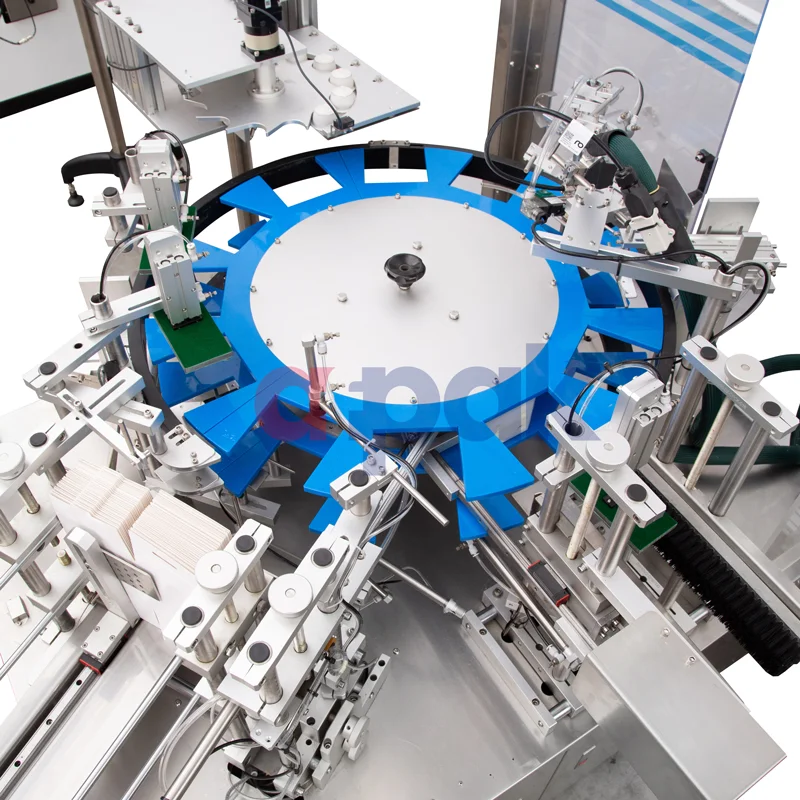

The rotary type differs from the linear type in design.

Single-lanes differ from two-lanes or four-lanes in size and production output.

Their specifications also vary by brand, due to each manufacturer using different designs and different electrical components.

3. What are the benefits can this 4-lanes coffee capsule production line machine brings me?

- Faster production

One man with one machine can produce more than 200 capsules/min, which is much faster than hand filling & packing or using semi-automatic machines.

It’s not hard to imagine how many capsules can one man produce when using some semi-automatic filling & sealing machine, deal with some steps by hand like loading capsules, loading foils, taking out sealed capsules, pushing the buttons, packing, and so on.

- High intelligence

The whole process becomes much easier and more reliable because most actions were done by machine in an accurate way and only little things are left to the operator.

This machine handles important steps like filling powder into capsules accurately, flushing enough nitrogen into every single capsule, sealing capsules with foils evenly and right in the position, and packing in a fixed and precise amount.

All you need to do is provide the necessary ingredients and let it proceed.

Besides, It has been equipped with kinds of warning devices, such as empty capsules deficiency alarm, powder deficiency alarm, failure of servo motor for filling alarm, etc., to make the operation easier.

Also, this machine has lots of sensing elements do automatic detection to control some performance of the machine, such as no cup no filling, no film no sealing, no cup stop machine, low-level powder feeding, open door stop machine, which protect the machine/operator from abnormal conditions.

What’s more, the operator can control every performance of this machine through a cantilever touchscreen such as speed, filling weight, filling auger speed, sealing temperature, etc., can even enter into a programming model to test every single step’s movements.

- Safety

As it was mentioned before, an “open door stop machine”, lots of sensing elements, and various alarms prevent the machine/operator from abnormal conditions, and an emergency button was equipped to force the machine to stop immediately when you push it in an emergency situation.

- Long usage time

All the core components come from well-known international brands, such as PLC/servo motor/servo driver/frequency converter come from Schneider, temperature controller/solid relay/programmer come from OMRON, and sensing elements come from Panasonic.

Each of them is reliable and extremely durable.

Besides, the quick-wearing parts such as the heating tube, thermocouple, sucker, joint, pipe, and screw, will be sent a few more sets together with the machine.

Furthermore, all the other parts of this coffee capsule maker machine are mainly made from stainless steel or aluminum, which will prevent them from rusting.

Its rated operating life is over 10 years.

- Low noise

We concentrated on improving the accuracy of parts processing and assembly, reducing the gap between the joints, reasonable usage of elastomer structure such as the spring right above the heat sealing head, reasonable configuration of weight distribution to adjust the center of gravity of this coffee capsule maker machine, to minimize the noise during machine running.

- Long-lasting flavor

This machine has a large amount of nitrogen blowing ports from the servo motor dosing station to the heat sealing station, to ensure the nitrogen content in the capsule, which is always higher than 95%.

Ultra-high food-grade nitrogen content ensures the long-lasting flavor of your products.

- Multi-function

You can change parts to produce different capsules.

That means you can produce K-cup, Nespresso, Dolce Gusto, Lavazza blue, and Tea capsules all in one machine, which saves money, saves space, and saves energy consumption.

Also, it can be customized to suit many different situations.

Such as the film loading station is optional to be chosen from die-cut lids or roll stock film, the cup dropping station is optional with or without flip, and the boxing part is optional to be chosen from 52 or 101, vertical or horizontal.

Besides, it’s expandable, which means many other functions are able to add to it depending on your needs.

Such as “Vibrating capsule sorting device”, “Liquid flavor dosing device”, “Anti-static device”, “Online weighting device”, “Automatic counting and distributing device”, and “Laser print code device”, etc.

- Higher profits

It’s a one-time investment that costs US$50,000 to US$200,000 in the first year when you purchase this 4-lanes coffee capsule production line machine.

The initial cost of purchasing and installing this kind of machine is high.

However, the profits begin to emerge during the long term run which can last for over ten years because of the huge time and manual labor saved by the machine.

As you know, the coffee capsules are a widely accepted product now, they became more and more popular due to the convenience and good quality coffee provided to people.

Just imagine that if you had a machine like this working for you nonstop, to meet the growing demand, continuously provide your customers with high-quality coffee.

4. What’s the vibrating capsule sorter used for?

It’s one of the solutions to feed empty capsules into the main part of the machine.

The vibrating capsule sorter can make up for the deficiencies of the “vertical capsule cut & drop device” to handle some unusual cases.

Sometimes capsules delivered to the factory in large boxes are not well sorted, so it is an extremely a waste of time to sort and move them to the machine by hand.

And sometimes the capsules are just not suited for “vertical capsule cut & drop device” for some reason the capsule feeding does not perform very well.

In these two cases mentioned above, the vibrating capsule sorter is a solution.

5. Tell me the main components of the coffee capsule production line machine.

- PLC

Programmable logic controller for controlling the machine.

You can key in the specifications and allow it to proceed with the pod packaging process.

Additionally, you can view the self-diagnostic results of the machine from the display screen.

- Relay

It’s a switch that electronically or electromechanically opens and closes circuits.

- Temperature controller

The CPU of the temperature controlling system.

It analyzes the temperature signal fed back by the temperature sensor, and determines whether to start heating or cooling, to control the temperature in the system to reach the set value.

- Servo motor

This is a liner actuator or rotary actuator that allows for the control of the angular or linear position.

You can also use it to control the acceleration and velocity of the coffee capsule maker machine.

It has a sensor that gives feedback of its operations.

It’s mainly used in coffee filling and film pulling stations of this machine where precise control is necessary.

- Vacuum feeder

It is a dust-free closed pipeline conveying equipment that conveys granular and powdery materials by means of vacuum suction.

The gas flow in the pipeline is formed because of air pressure difference, and the powdery materials are driven to move, thereby completing the conveying of powders.

- Auger dispenser

It is a vertical powder dosing device.

The powder is evenly distributed on the threads, so controlling how many turns the auger rotates is equal to controlling how many materials are dosed.

- Pneumatic cylinder

It is used to achieve repeated liner or circular displacements, or even gripping actions.

This coffee capsule maker machine is equipped with dozens of these elements.

6. Can I produce both K-cups and Nespresso capsules in one machine?

No problem.

Only need some switch of parts, including molds, heat sealing head, and filling head for another capsule.

Also, there shall be some changes in parameters on the control panel, including filling weight, the number of capsules per pack. All of these are easy to do so you need not worry about the extra parts and the operations during the switch.

We’ll send all the parts you’ll use together with the machine, and provide professional guidance videos and online video support when you go to switch models.

7. How does the coffee capsule maker machine ensures filling accuracy?

It’s equipped with a “vertical auger filling system” driven by a high-precision servo motor and controlled by advanced PLC to ensure filling accuracy.

The “vertical auger filling system” is a well-known mature technology for various kinds of powder filling and is used worldwide now.

It ensures a filling weight deviation of fewer than ±0.2 grams.

In addition, it’s also equipped with a “constant speed mixing device” inside the hopper to ensure even and continuous powder loading to the vertical auger.

Meanwhile, a special filling head right below the auger ensures stable dosing flow and keeps the powder from spreading out.

8. How does the coffee capsule maker machine ensures tight sealing?

First, it ensures foils loading to the right place.

When it’s equipped with a “rotating cylinder foils suck & load system”, pre-cut foils will be sucked from a fixed position to the top of capsules right in the center.

When it’s equipped with a “roll stock foils cut & seal system”, roll film will be pulled by a high-precision servo motor which makes sure it walks a fixed long distance, then it is cut down and in the meantime sealed on the top of capsules with no position change.

Second, it ensures even and rapid heat transfer from the sealing head to the seal.

Every heat-sealing head is made of high thermal conductivity material(brass) and equipped with two heating pipes to make sure fast heating and heat transfer, it’s bottom is fixed with a large spring for shock absorption as well as pressure balance around the seal.

Besides, it’s equipped with an advanced OMRON temperature control system which makes the temperature detection and controls more accurate.

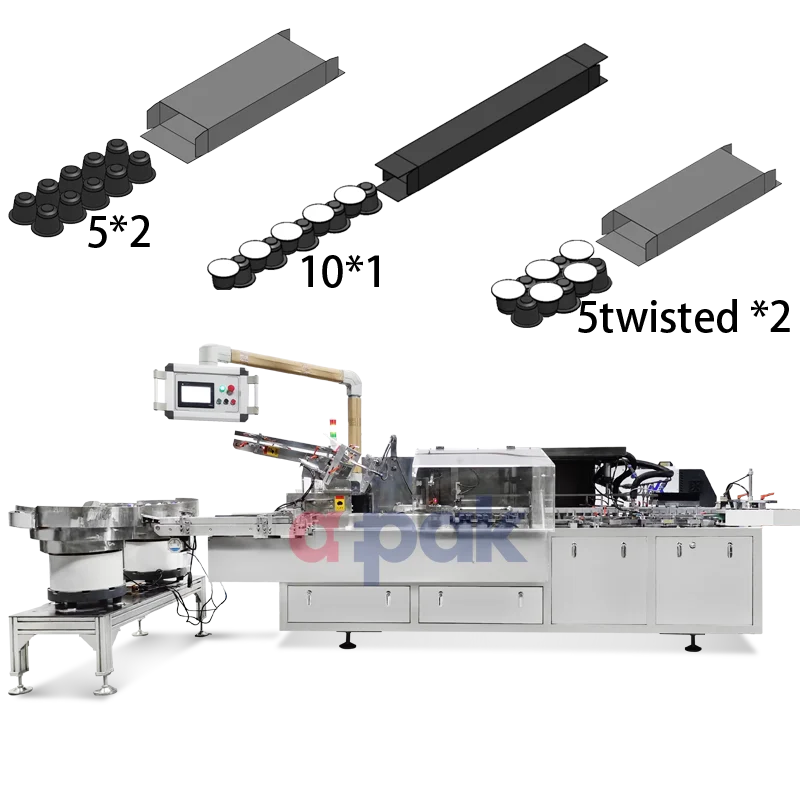

9. Can this coffee capsule maker machine pack different kinds of boxes?

Definitely.

It is compatible with different box sizes, such as long boxes in which capsules will be packed in one or two rows, and square boxes for fixed quantity bulks.

Of course, these boxes shall be well pre-folded which means there are prepared lines made by folding in them.

Meanwhile, the machine needs some parameter changes on the control panel to understand what boxes it’ll pack.

10. Where to buy this coffee capsule production line machine?

Generally, this kind of machine can be purchased online or from physical stores.

Buying online is a very convenient way that you can choose from various types and styles at home without going all over the mall, and the price is relatively cheaper.

However, it’s hard to check out or inspect the machine by yourself whether it can function well.

So it is important that the machine is sold by reliable enterprises when buying online.

Even though it’s pros and cons, you can buy our machine online with confidence.

At first, we have more than 10 years' experience in making this machine.

Our technology is very mature and we’re experienced in after-sale service.

Moreover, we’ll communicate with you enough, give you many details and working videos of this machine during your consultation to find out what you need and what we have.

Second, we have clients all over the world. That means you have the chance to visit one of them who is close to you to check how the machine actually works before you make a decision.

11. What should I consider when importing a coffee capsule production line machine?

Before you proceed to purchase or import a coffee capsule maker machine, let us look at the key considerations.

You need to look at the technical specifications, as well as other key factors such as below.

① Budget

You might want to start a business on a low budget thus prompting you to acquire a second-hand machine or a semi-automatic one.

With the right budget, you should opt for a new full-automatic coffee capsule maker machine.

② Price comparison

You can try to get a wide range of prices for the coffee capsule maker machine from different suppliers.

Then you have to look at and compare the technical specifications behind every machine that dictates the kind of pricing.

③ Manpower engagement

Look at this factor in terms of either purchasing an automatic or semi-automatic machine.

Semi-automatic one requires more manpower engagement leading to additional processing costs.

④ Production capacity

You need to look at the production capacity and ensure that it fits your requirements.

Also, you need to estimate the market demand for your products in order to find out your requirements.

⑤ Rate of air consumption

You need to understand the rate of air consumption of the machine to avoid any complications.

⑥ Space requirement

You need to know the space the machine takes in the installation and operation process.

It allows you to prepare the size of the room where you will place the coffee pod packaging machine.

⑦ Power requirement and consumption

You have to make sure that the power requirements fit the domestic power phase.

If not, you will have to request a power configuration of the coffee pod packaging machine.

⑧ Warranty period

You have to check the warranty period in detail before you place an order.

You need to look at the parts that come with the warranty period and the parts that don’t.

⑨ Installation and training

You need to confirm whether it’s necessary for field installation and training.

You need to confirm whether you need to pay for the field installation and training.

⑩ After-sale service

You have to check what after-sale service will be provided.

How quick and by what response will be provided?

What will the supplier do if problems come out during production?

What if some components are broken?

Conclude

It is about time you jump on the bandwagon and get your own coffee capsule production line machine. AFPAK has a wide variety of top-grade machines which you can choose from. Our machines are specifically designed to keep you ahead of the competition.

We make sure to make your investment worth it with premium quality products. All of our machines are made to precision with incredible attention to detail. We bring new updates every year to ensure the latest standards are met. You will not find a more advanced, effective, efficient, and durable coffee capsule production line machine anywhere else.