I. Product introduction.

1、This semi auto tin can seamer is mainly suitable for sealing and packaging of various round PET plastic, iron, aluminum, paper cans, etc. With advanced product design, reasonable structure, and easy and light operation, it is the necessary ideal packaging equipment for food, medicine, tea, and chemical industries.

2、The main body of this semi auto tin can seamer is made of stainless steel, with a beautiful appearance, which meets the design requirements of most standard production workshops.

3, using a single motor work, each part processing precision, production technology, and technology after the company's long time precipitation and continuous improvement, has the advantages of low noise, and low failure rate.

4, the semi auto tin can seamer is in line with national standards, ministerial standards, and enterprise standards, and after strict inspection and testing of the full range of qualified, before permission to leave the factory.

II, the main parameters of semi auto tin can seamer

1、Material: stainless steel

2、Number of sealing cans: 1

3、Sealing speed: 20-25 cans/min

4、Sealing height: 40-200mm

5、Applicable bottle diameter: 50-153mm

6、Working voltage: AC220V 50/60Hz

7、Power:0.25~0.37KW

8、Weight: 130KG

9、Size: 560*450*1450mm

II, Performance description of semi auto tin can seamer

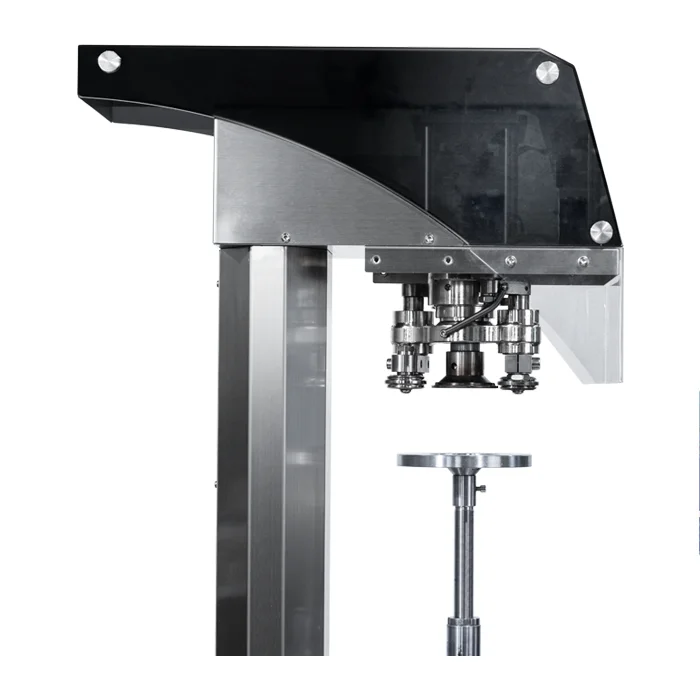

1, sealing using two sealing wheel sealing, the head knife to complete the rolled edge, the second knife to complete the crimping, simple structure, easy to adjust.

2, using the latest generation of mechanical design, the sealing process can not rotate, sealing hobs rotate to complete the sealing, reliable and safe, to avoid the cans filled with products shifted and scattered, especially suitable for fragile products and liquid products sealed can packaging.

3, New and improved, the motor is lowered, in line with ergonomics, effectively preventing the machine from the danger of tipping over during transportation.

4, The new design is equipped with visualization screen, which is convenient for real-time statistics of output. Increase the interval time of sealing cans in automatic mode, adjustable automatic running speed, making it more humane to use

5, The hobbing work and can lifting is controlled by mechanical cams, which is stable and reliable in operation.

6, Simple operation, just one key to complete the sealing.

7, High processing accuracy, the main body is designed and manufactured with all stainless steel materials, in line with the design requirements of the production workshop.

8, Changing the caliber needs to replace the mold: pressure head + tray, the replacement time is about 30 minutes.

9, change the can sealing height, no need to replace the accessories, using manual rotation of the pallet, the adjustment time of about 5 minutes. If the can height difference is too big, it needs to replace the pallets

10, Very low defect rate, less than one ten-thousandth for iron cans, less than one-thousandth for plastic cans, and less than two thousandths for paper cans.

11, the pressure head is made of 45# steel quenching treatment, hardness more than 50 degrees, and service life of more than 1 million cans.

12, rollers using 440C stainless steel rollers, the life expectancy of more than 6 million times sealing