Is It As Good As Water Flow? Things you Need to Know

To save you from worries, here are some facts you need to know about ourrotary k cup machine:

Because the demand for k cups is becoming larger, more manufacturers are joining the ranks of K-cups production, and there are numerous manufacturers of K-cup filling packaging machines on the market, so I think you must have encountered many questions in the process of finding your own filling packaging production equipment, and now I will combine my years of experience in the field with feedback summarized below for your reference:

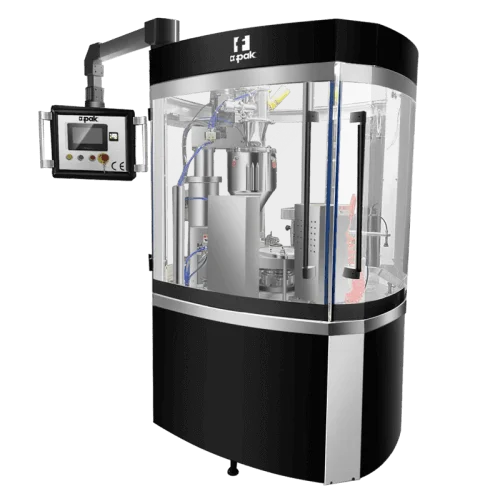

What is the Rotary K cup Machine?

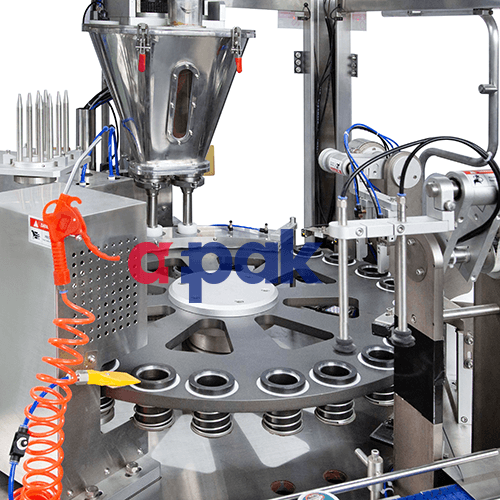

Rotary K cup machine is a class of professional filling and sealing k-cups professional equipment, and rotary type machine has a circular production platform, and no chain drive, the motor directly drives the rotary table turntable to guide k cups to complete the filling and sealing process.

What are the advantages of the Rotary K cup machine?

Because of the structure of the machine, compared to linear machines, it has:

- More accurate movement:Because the movement of the disc is driven directly by the motor, no need to pass the chain, so the whole machine is the more stable and smooth operation

- Faster production.Compared to the same type of linear machine equipment, the production speed of the disc machine is significantly faster because it has a short moving stroke and can complete the operation of each station faster

- Easier to change molds.The Rotary K cup machine makes it easier to change molds to produce other varieties of coffee capsules by changing only 10-20 mold cores.

- Simpler to use and maintain

Simple Compare of AFPAK RN1S and RN120 Rotary K cup Machines

| Modèle | RN1S | RN120 |

| Capacité | 50-70 cpmin3000-4200 cph | 100-120 cpmin6000-7200 cph |

| Filling system | Servo Motor driver Vertical auger to fill | |

| Tête de remplissage | 1 tête | 2 têtes |

| Gamme de remplissage | 1-20 grammes réglable | |

| Tête d'étanchéité | 1 tête | 2 têtes |

| Sealing temperature | 0-400 cent degree adjustable | |

| Temps de scellage | 0.1-0.8 seconds | |

| Sealing pressure | 0.1Bar -0.8 Bar | |

| Machine Layout | 1200*1200*2000 mm | 1950*1800*2000 mm |

| Poids de la machine | 700 KGS | 1200 KGS |

What are the standard functions of a rotary K cup machine

Generally speaking, the functions of rotary k cup machines are

- K cup Dropping:

The empty k-cups you receive are stacked and require the machine to be separated one by one, so this step is essential. Compared to the RN1S, the RN120 has a larger cup storage space, which can store more cups and reduce labor, but both machines have large enough cup bins to meet the demand for only 5-6 servings per hour.

Empty k cups are made of plastic materials, which are hard, not easily deformed, and can be stacked well, so vertical dropping is the most suitable method to adopt.

The principle of the vertical cup drop method is that after the cups are stacked, there will be a gap between the two cups. Our special cup-separating device is used to separate the upper and lower cups, and the bottom of the cup is sucked by a suction cup. Thus 100% cup dropping could be achieved

- No Cups No Filling sensor:

This is a very critical step in the intelligence of the machine, when the machine detects the lack of cups in the mold core, then the station will not work in the subsequent filling and sealing process, so as to keep the machine clean and tidy

- High filling accuracy:

AFPAK have been fortunate in working with a senior equipment specialist in the United States to develop the filling system we are using today to ensure that every capsule you produce is of the correct weight.

Schneider Servo Motors control the coffee filling augers. Each auger is equipped with a motor. Each auger’s parameters are easily to adjust.

Designed Vertical augers guarantee coffee going down evenly and rapidly.

A stirring motor is equipped to stir the coffee inside the tank.

The tank is visible to allow you to check the inside easily.

A vacuum coffee feeder is applied to feed coffee from your storage tank automatically, time-saving for the operation.

The filling nozzle will cover the capsule’s edge fully to make sure all coffee is filled inside without leaking.

With a vacuum coffee supply system equipped, you just need to put the ground coffee storage tank aside from the machine which will supply coffee automatically.

All coffee contact parts are made from food-grade SUS 304 materials.

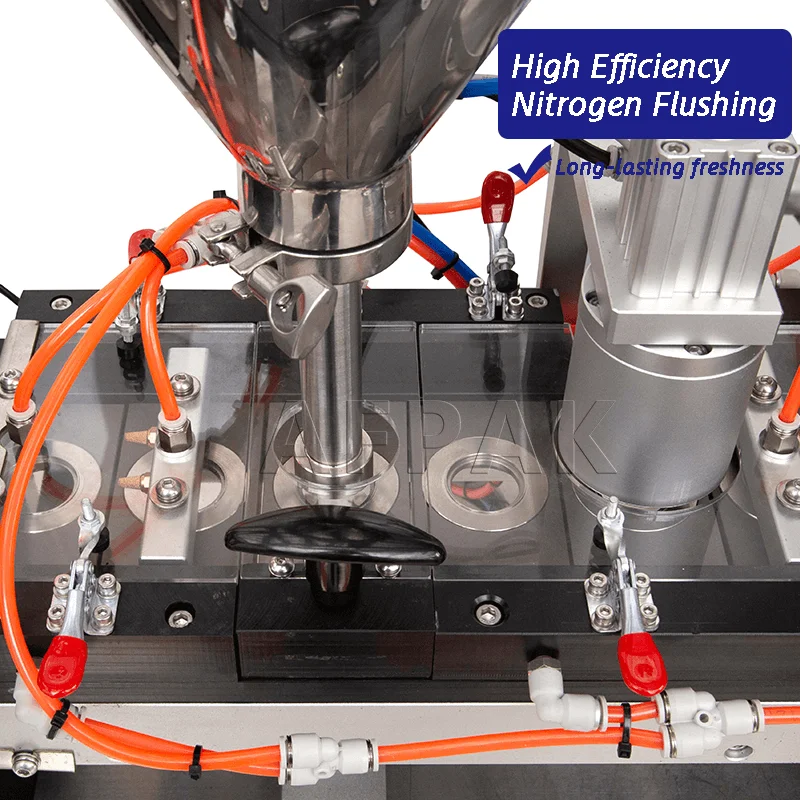

Nitrogen gas flushing will keep your coffee under protection.

- Coffee tamping and capsule edge cleaning system:

This is a crucial step to ensure the quality of the seal. Powder residue not cleaned leads to poor sealing, low brewing effect and nitrogen gas lost, thus reducing the shelf life of Coffee

Strong vacuum pressure can remove all coffee residue on the capsule edge.

The coffee is tamped to make it much firmer for better brewing.

Residue collection bottles are easy to clean.

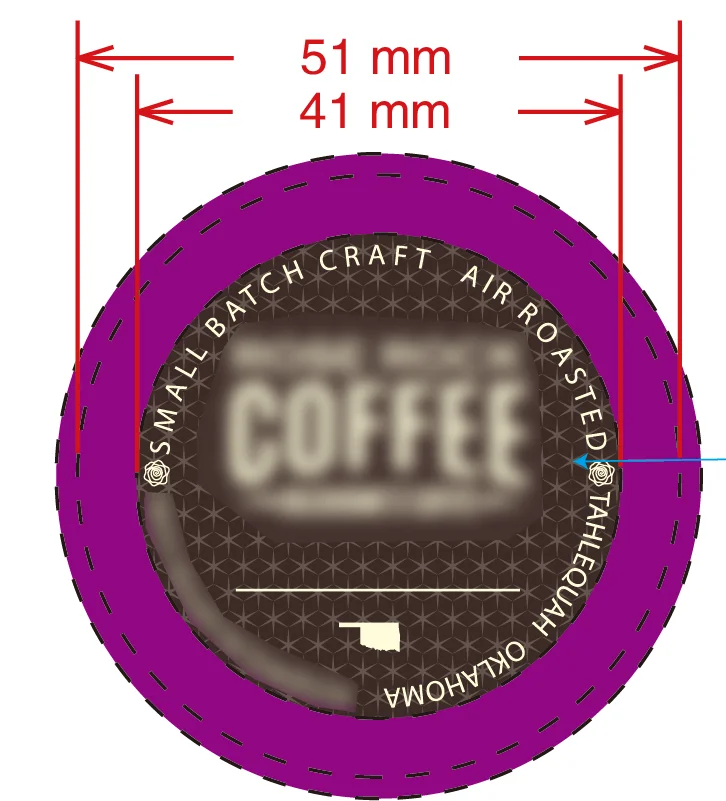

- Pre-cut lids pick and place system:

Widely use for precut lids with aluminum or paper materials

Lids loading tunnel can load 1000 pcs lids.

Designed for easy loading the lids.

- Lids Sealing system

The whole device is driven up and down by the main motor. The safety of chain, mold plate and sealing device is effectively ensured.

Rapid sealing technology can protect the capsules and sealing materials.

The sealing temperature can be adjusted from 0-400 degree Celsius.

Japan-made heat insulating material is adopted to protect the cylinder and parts related to the heaters from getting damage by high temperature.

Heaters and thermocouples are easy to change.

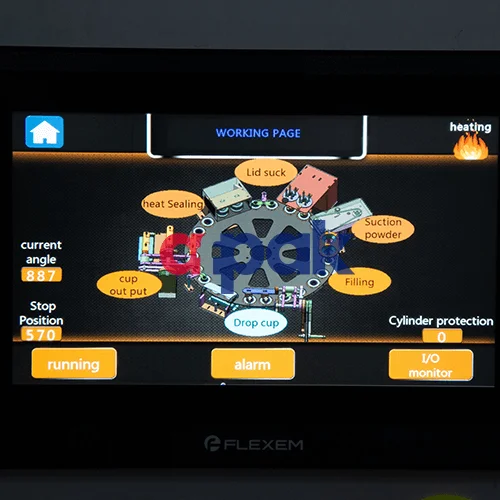

- Users-friendly Human-machine Interface Control System

Easy to operate. English can be set as the operation language.

Operation State is clear at a glance.

The counting function counts the number of cups produced.

It can work for 24 hours working without stopping.

Fault display will help indicate issues.

- Smart running

Intelligence is a vital part of Industry 4.0. AFPAK is equipped with many intelligent induction systems for you, which can better help you control the production line.

No capsules, there will be no filling or sealing operated.

No lids, there will be no sealing operated and the machine stops working.

If there is a continuous lack of cups in the mold, the machine will stop and raise the alarm.

- Control and electrical box

All the electrical parts are mainly from Schneider and Omron to ensure the working accuracy of all functions.

Unique high-tech micro-computer controller has powerful fault diagnosis and protection functions.

All the parts are standard that it is easy for you to find the replacing ones.

The spare output port can help realize multi-unit chain control and remote diagnosis control.

- Finished capsules/cups discharging

Stable and orderly grab system.

Precise rotation and placement system.

Vacuum or mechanical claws. Pick and place the finished capsule on the 1.8 meters conveyor belt. The standard conveyor will be placed at 90 angles.

- Nitrogen input system and protected device

Use organic glass to cover the mold, from empty capsule feeding station to sealing lids station, all processes are flushed with nitrogen. Besides, the powder hopper also has a nitrogen inlet, which can guarantee coffee production is under the modified atmosphere, it will reduce each capsule’s residual oxygen content lower than 3%, keep coffee aroma, prolong coffee shelf life.

- Vacuum feeding machine

Automatically transfer powder materials through the pipe from the holding floor tank to an auger hopper.

What are the optional parts of the rotary K cup machine?

Option 1: UV LAMP

Ultraviolet disinfection lamp, it is to kill with ultraviolet ray to include bacterium reproduction, bud, branch bacili, coronavirus, fungus, rickettsia and chlamydia to wait, the body surface that each is polluted by the afore-mentioned virus, water and air, can use ultraviolet ray disinfection

Option 2: Anti-static device

The main function of the ion fan is to eliminate static electricity, which has excellent performance to prevent electrostatic pollution and damage. Because the coffee particles are always moving and rubbing against each other, they must generate static electricity. Removing this static electricity is more conducive to smooth filling, and also protects the filling system in a sense.

Option 3: Micro liquid flavor adding device

Add Micro flavor liquid into capsules, Such as Vanilla, Hazelnut different tastes, The pump power is from Compressed air, spray one drip liquid flavor into the capsules.

Option 4: The online check weighing system

After finished capsule discharging, the online check weighing the online weighing system measures the weight of each product. The products that reach the set weight value will be transported to the finished product box smoothly, and the defective products will be identified and enter the rejection box. Use motor drive loading cell platform move up and down to check every capsule’s weight

Option 6: Remote control

Before the machine leaves the factory, the program and logic are set according to the current requirements of the customer. If the customer wants to change some software logic according to the actual needs in the future, the engineer can control the change remotely in China, which saves them time and economic cost of the customer.

How Long does it take for me to receive the rotary k cup machine I ordered?

It takes up to 5 weeks to manufacture and deliver your rotary k cup machine with no machine customization but may take up to 8 weeks with customization. This is because we ensure that every customized rotary k cup machine you order is perfect in operation

What do I do if my rotary k cup machine order is delayed?

If your order is over 2 weeks later, contact our customer support for further assistance. We’ll be sure to address your concerns immediately.

Due to the COVID-19 pandemic, please expect minimal delays in order processing and delivery.

Why the AFPAK Rotary k cup machine?

Our rotary K cup machine products are made with the top brands of electrical components and the latest technology, all at an affordable rate. Our 10+ years of manufacturing experience will ensure you get the best rotary k cup machine

Can you replace products that are damaged during delivery?

Although we ensure top-notch safety for all our orders, mishaps do happen. When they do, please contact customer support on our site. They’ll advise you accordingly.

Should you have any other questions, welcome to contact AFPAK