Feeling overwhelmed by the thought of starting K-Cup production? Don't worry, many people have the same problem. It can seem like a huge step.

The fastest way to start K-Cup production is to invest in a high-quality, automated filling and sealing machine from a reputable manufacturer. Consider factors like production speed, material compatibility, and after-sales service to pick what fits your business best.

The K-Cup market is big and growing, so getting started now is a good move. But, you need to understand the market first. Let’s dive in.

K-Cup Market Insights and the Necessity of Automated Production?

Struggling to keep up with the booming K-Cup demand? Manual production just doesn't cut it anymore. You need a better way.

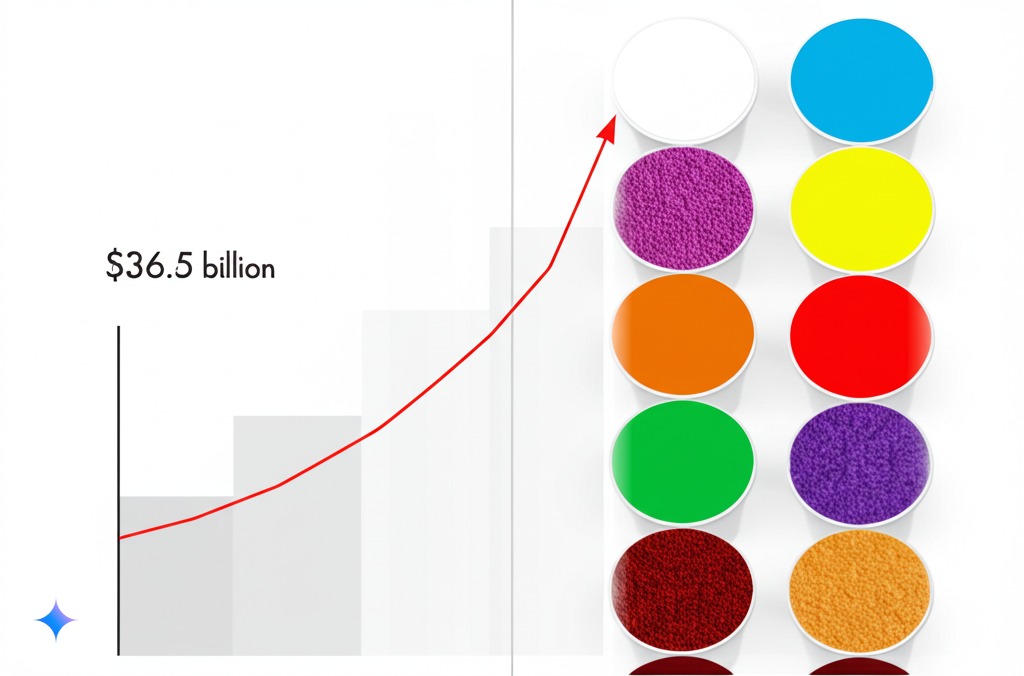

The K-Cup market is projected to reach approximately $36.5 billion by 2025, growing at a rate of about 6.5% each year. This huge growth shows a big need for automated production to meet demand efficiently.

The K-Cup market is very exciting. People want convenience and variety. This drives the demand for K-Cups. But, there are also challenges. There's more competition now. Also, people care about the environment. The future will involve sustainable options. Think recyclable or compostable capsules. Also, expect smart features in K-Cup machines. These will make the user experience even better. To start quickly, you need a reliable partner. Choose a manufacturer that produces excellent quality and high cost performance,like AFPAK. Our RN1S K cup filling machine model, for example, we sell more than 10 units to the US market every year. And the quantity is constantly expanding.

| Feature | Insight | Impact on Production |

|---|---|---|

| Market Size (2025) | ~$36.5 Billion | High demand, need for large-scale production |

| Annual Growth Rate | ~6.5% | Continuous increase in production required |

| Sustainability | Focus on recyclable/compostable capsules | Need for machines compatible with new materials |

| Smart Features | Innovation in K-Cup machines | Adaptability in production lines for new K-Cup designs |

| Competition | Increasing | Need for efficient and cost-effective production |

| Environmental Issues | Growing concern | Shift towards eco-friendly production methods |

Building an Efficient K-Cup Automated Production Line: Core Elements Analysis?

Confused about what makes a K-Cup production line work well? The many parts and steps can be hard to get your head around. Let's explore it.

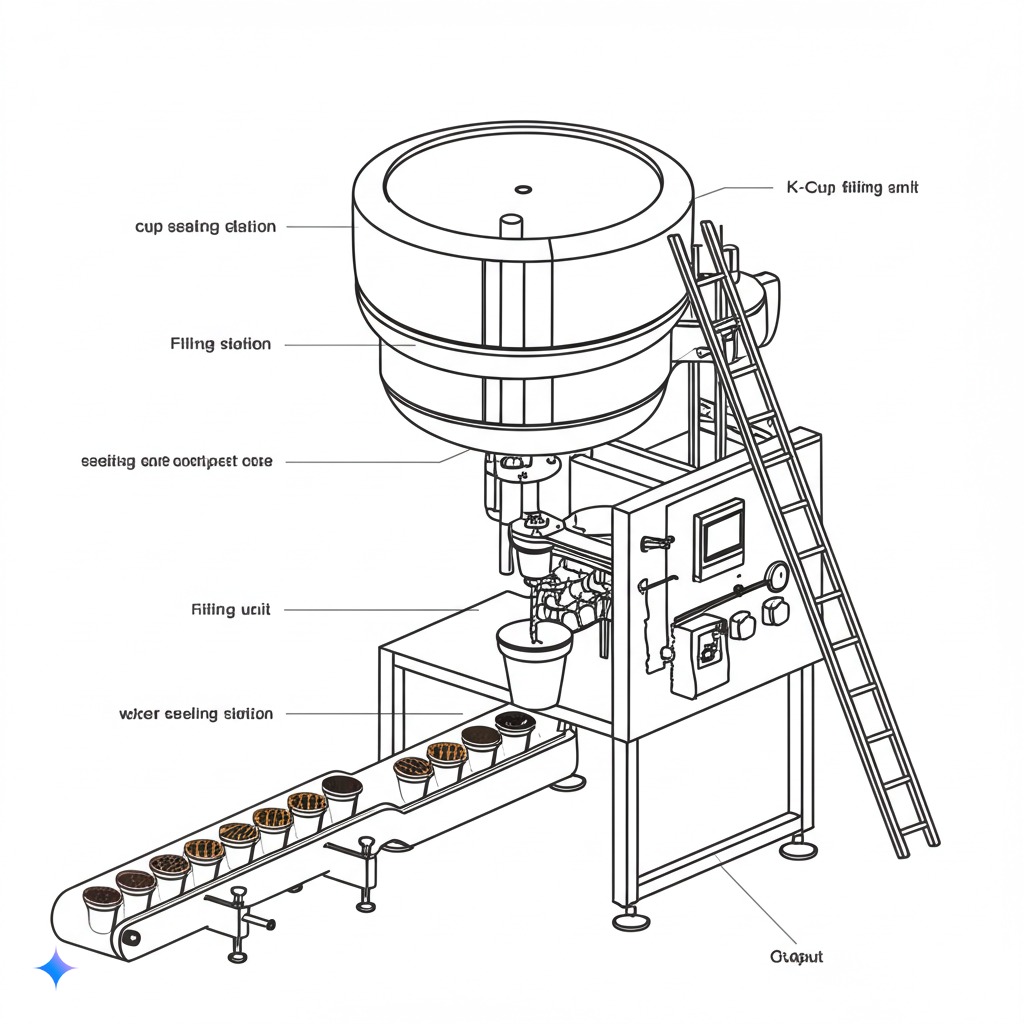

An efficient K-Cup production line is built on key components: the cup denester, filling station, sealing unit, and output mechanism. Each works together smoothly to ensure fast, quality production. We use the best parts for better output.

Think of a K-Cup line like a team. Each part has a job. The cup denester feeds empty cups. The filling station adds the coffee or other product. The sealing unit closes the cup. The output mechanism collects the finished K-Cups. All these parts must work together, perfectly. At AFPAK, we use top-quality components. For example, we use branded servo motors. These provide more stable and accurate filling. We use branded sensors to check the quality. This reduces waste. The machine frame is strong and durable. This makes it long-lasting. Control system is easy to use. It makes managing the process very simple. Regular cleaning is also important. It keeps the line running smoothly.

| Core Element | Function | AFPAK's Approach | Benefit |

|---|---|---|---|

| Cup Denester | Feeds empty cups into the line | High-precision denesting system | Accurate cup placement, reduces jams |

| Filling Station | Dispenses product into the cups | Branded Servo motors for auger filling | Precise and consistent filling, minimizes waste |

| Sealing Unit | Seals the filled cups | High-quality sealing heads | Secure seal, prevents leaks and maintains freshness |

| Output Mechanism | Collects and organizes finished K-Cups | Automated counting and stacking | Efficient packaging, ready for distribution |

| Control System | Manages the entire production process | User-friendly PLC and touchscreen interface | Easy operation and monitoring |

Customized Solutions: Meeting Your Unique Needs?

Frustrated with one-size-fits-all solutions? They often don't meet specific needs. You need a K-Cup line that works for you.

Customized K-Cup production solutions address your specific needs, like different cup sizes, filling materials, and production volumes. The price for an empty K-cup is about $0.04, and a lidding film is $0.009. These prices are always changing.

Every business is different. You might have a unique cup size. Or, you might fill something other than coffee. Maybe you need a very high production speed. Or, maybe you're starting small. A standard machine might not work. That's where customization comes in. We work with you. We find out what you need. Then, we design a machine that fits. We can adjust the filling system. We can change the sealing unit. We can even modify the output. This way, you get the best results. Also, the price of materials is important. An empty K-Cup is about $0.04. The film is about $0.009. These prices change with the market. So, we help you find the best deals. This keeps your costs down.

| Customization Aspect | Example | Benefit |

|---|---|---|

| Cup Size | Adapting to different K-Cup diameters | Versatility in product offerings |

| Filling Material | Handling coffee, tea, cocoa, etc. | Broadens market reach |

| Production Volume | Scaling machine capacity up or down | Matches production to demand, optimizes cost |

| Sealing Type | Different sealing film materials | Flexibility in packaging options |

| Machine Footprint | Adjusting size to fit available space | Efficient use of factory floor |

| Budget | Offering different price with different configuration | Meeting your budge by choosing the best option. |

Sustainable Development: The Future of Green K-Cup Production?

Worried about the environmental impact of K-Cups? Traditional plastic cups create a lot of waste. There's a better, greener way.

Sustainable K-Cup production focuses on using eco-friendly materials, like compostable or recyclable cups and lids. AFPAK is researching fully compostable sugarcane-based K-Cups, and PLA cups are widely available.

Consumers care about the planet. They want sustainable choices. This is changing the K-Cup market. Traditional K-Cups are often made of plastic. This plastic ends up in landfills. It takes a long time to break down. This is bad for the environment. The solution is to use different materials. Compostable materials break down naturally. Recyclable materials can be used again. This reduces waste. AFPAK is working hard on this. We're researching sugarcane-based K-Cups. These will be fully compostable. Also, there are already PLA K-Cups available. PLA is a plant-based plastic. It's a better option than traditional plastic. Choosing sustainable options is good for the planet. It's also good for business. It appeals to eco-conscious consumers.

| Sustainable Material | Description | Benefit |

|---|---|---|

| Sugarcane-based | Fully compostable, made from sugarcane waste | Breaks down naturally, reduces landfill waste |

| PLA | Plant-based plastic, compostable | Renewable resource, lower environmental impact |

| Recyclable Plastic | Can be processed and reused | Reduces the need for new plastic production |

| Paper/Filter | Biodegradable | Compostable, reduces plastic use |

| Aluminum | Infinitely recyclable | Closed-loop recycling, highly sustainable |

Success Story Sharing and Outlook?

Want to see how it all comes together? Let's look at some real-world examples. It's inspiring to see others succeed.

AFPAK has many successful users in the United States and other countries, and they continue to receive positive feedback.

We have customers all over the world. They use our machines to produce K-Cups. They're happy with the results. You can see some of their feedback on our Facebook page. [link to first video]. [link to second video]. These videos show our machines in action. They show how our customers are growing their businesses. This is what motivates us. We want to help you succeed. We believe in long-term partnerships. We provide ongoing support. We help you with maintenance. We help you with upgrades. The K-Cup market will keep changing. We'll keep innovating. We'll continue to provide the best solutions.

Here some links to demonstrate our success.

- https://www.facebook.com/shanghai.afpak/videos/434977226122033

- https://www.facebook.com/shanghai.afpak/videos/869483235401009

| Aspect | Detail | Outcome |

|---|---|---|

| Customer Base | Numerous users in the US and globally | Wide adoption of AFPAK machines |

| Feedback | Positive reviews and testimonials | High customer satisfaction |

| Support | Ongoing maintenance and upgrade assistance | Long-term partnerships and customer loyalty |

| Innovation | Continuous development of new features | Staying ahead of market trends |

| Market Outlook | Continued growth and evolution of the K-Cup market | Opportunities for expansion and new product lines |

Conclusion

Starting K-Cup production requires careful planning and the right equipment. By working with a good partner like AFPAK, you get a quality, customized, and maybe a sustainable solution.