As the actual user of the K cup filling machine, you need to let it know some necessary parameters, such as the filling weight, only then can it fill to capsules at the fixed weight you want.

In fact, it’s not yet enough for the machine to achieve the special filling weight you need, because it has not been equipped with an automatic filling weight adjustment function.

That function means as long as you set the [Fill weight] parameters, the machine can try different filling weights again and again automatically until the weight reaches the goal.

As the K cup filling machine will be designed to become more intelligent, that function may become a standard in the future.

For now, in addition to the filling weight, the K cup filling machine also needs to know a coefficient called [Fill ratio] to find out how many turns the auger is needed to make.

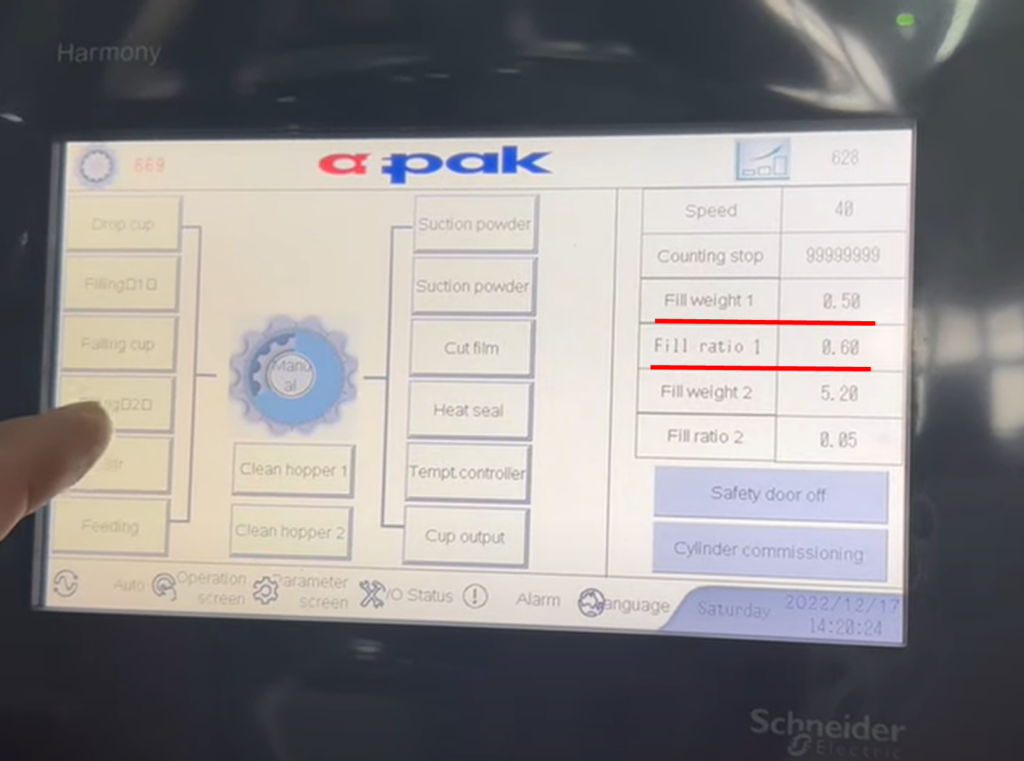

In this article, we will talk about how to set these two filling parameters on the control panel(touch screen) of the K cup filling machine made by AFPAK.

One is [Fill weight] and another is [Fill ratio] as shown in the picture below.

Operation Guidance

Step 1: Preparation.

First, confirm that your K cup filling machine is powered on, the compressed air is well connected, and there are about 60% ~ 80% full of coffee powder in the hopper.

Then loosen the fixing screw a little bit so that the whole hopper with the filling nozzle can be moved out.

Then turn the hand wheel to lift the whole hopper a little higher to where it can be turned out of the big round table.

After moving the hopper out, place a powder collection box under the filling nozzle.

Prepare a scale on your side, put an empty cup(such as a K cup) on, and zero it.

Step 2: Change the parameters on the screen for the first time.

Press the [Operation screen] button in the bottom of the screen.

Then press the [Auto] button in the middle of the screen to switch the mode to “Manual”.

Then press [Filling][Stir] two buttons on the left of the screen to turn these two functions on.

Press the value of the filling weight which is on the right of the [Fill weight] label to enter into the value modification interface.

Fill in the value that how many grams of the coffee powder you want to load into each capsule, then press [Enter] to save this modification.

As for the [Fill ratio], keep the factory setting value for the moment.

([Fill ratio] is one of the coefficients determining how many turns the auger is required to achieve the [Fill weight]. You need several times to try later to get the right value.)

Step 3: Test running for the first time.

(The first try to find out whether [Fill ratio] is just the right value by running the machine and weighing the filled K cups.)

Press the green RUN button at the bottom of the control panel to run the machine.

(Actually only the [Filling] and [Stir] two functions will be active.)

Ignore the first few times of filling(about five times), and let the powder be filled into the collection box.

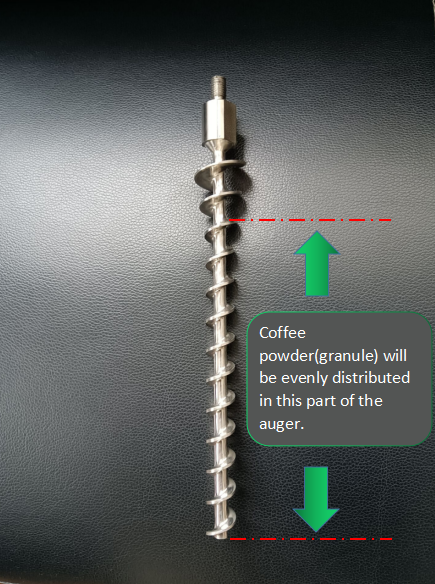

(In this process, the coffee powder will be gradually and evenly distributed to the auger, and only then you can weigh the filled K cups.)

Put the prepared empty cup under the filling nozzle to get the one-time filling powder and then weigh it.

(Write down the weight if you think it’s necessary.)

Empty this filled cup and repeat the above actions(filling and weighing) about five times.

Press the red STOP button at the bottom of the control panel to stop the machine.

Calculate the average filling weight and compare it with the [Fill weight] value that you set on the screen before.

Step 4: Change the [Fill ratio] value on the screen.

If the average weight in step 3 is larger than [Fill weight], then decrease [Fill ratio] by 0.01 or 0.02.

If it is lower than [Fill weight], increase [Fill ratio] by 0.01 or 0.02.

Else it means now the [Fill ratio] is just the right value and needs no changes or further tests.

Step 5: Repeat step3 and step4 until the average filling weight is almost equal to [Fill weight].

The “almost equal” means the deviation is little than 0.1.

It should be noted that the hopper needs to be refilled in time to keep 60% ~ 80% full of coffee powder inside during the tests.

The following video is a sample of how to operate our rotary K cup filling machine.

The Principle of Auger Filling System

Because the auger will be evenly filled with coffee granules which are not very much in particle size, the weight of the coffee on each turn (or each small section) of the threads is almost the same.

So if the auger rotates a fixed number of turns, it can fill a fixed number of coffee.

The servo motor is used to precisely control the number of turns of the auger.

As long as the machine knows the [Fill weight] and [Fill ratio], it will calculate how many turns the servo motor needs to rotate the auger each time.

Remarks

The weight of coffee on each turn of the auger will be influenced by several factors: coffee beans, roasting, grinding(particle shape or size), auger size, and the amount of coffee powder left in the hopper(the more powder in the hopper, the tighter they are pressed on the auger).

All these factors lead to different [Fill ratio].

During the real production process, it is probable that different coffee powders will be used to fill into capsules, and this is the time that the [Fill ratio] parameter is need to be reset.

The filling accuracy that can be achieved now is ±0.2g.

After the complete set of parameters, the hopper needs to be turned back to its original position.

This includes the horizontal position and the vertical position.

If these positions are not easy to find, it’s better that you mark them before you start to set filling parameters.