Since the outbreak of covid-19, working in the office is much more limited, and more and more people start to work from home.

This has greatly increased the consumption of instant coffee at home with K cups consumption increasing by 7%.

Even now it is getting better with the pandemic and traveling is basically the same as before the epidemic, the amount of consumption of instant coffee is continuously increasing, which means more and more coffee lovers become K cup fans.

The higher demand for K cups has driven the industry of K cups related machine manufacture to thrive.

A great amount of K cup business has become larger from small.

A lot of new startups worldwide try to seize the opportunity to enter the K cups business.

Hence to help those small to big businesses, AfPak has launched AF-HB410 high-end filling and sealing packaging machine with 4 lanes to boost efficiency and productivity.

It is a machine, that not only can it complete the filling and sealing of various types of coffee pods or cups, but also it could pack the filled and sealed pods or cups connected with the box packaging machine.

The main structure of the AF-HB410 high-end filling and sealing packaging machine

The below photo of the AF-HB410 filling and sealing packaging machine has displayed its two major parts, which are the filling and sealing machine AF-H4 and the box packaging machine AF-B10.

The below video presents how the AF-H4 fills and seals the coffee k cups.

AF H4 Kcup filling sealing machine is a highly efficient machine that could fill and seal 160-200 cups each minute. It has 4 lanes to fill and seal so to improve efficiency. And lanes could be customized, which means customers could choose 2 lanes, 4 lanes, 6 lanes, or even more.

AfPak offers a turnkey solution to increase customers’ workshop efficiency and productivity it is not necessary for customers to find other box packaging machines to pack cups or pods after the cups or pods are filled and sealed. To maximize automation in the customer’s factories, AfPak also offers a box packaging machine that is connected to the filling and sealing machine to form a complete production line. This time is saved and customers do not need further pack the cups or pods by themselves. It is hence labor-saving.

The Parameters of the AF-HB410 high-end K cup filling and sealing packaging machine

| Model | AF-H4 | AF-B10 |

| Output speed | 160-200 cups/min | 20-40 boxes/min dependent on packaging type |

| Packaging type | 5*2,10*1 or other customized requirement | |

| Voltage | 3 phases* 220V, 50/60hz (adjustable) | |

| Power | 30A, 5-6kW/h | |

| Air consumption | 45 scfm | |

| Nitrogen consumption | 30 scfm | |

| Dimension | 4800mm*1000mm*2300mm | 3500mm*1500mm*1650mm |

| Over temperature | 5℃-35℃ | |

| Humidity | ≤85% | |

| Overall weight | 1500kg | 1000kg |

How the AF-HB410 high-end k cup filling and sealing packaging machine works

- Empty cups loaded.

As below, there are 4 lanes of silo to load empty cups, which could be customized, such as 6 lanes or 8 lanes. Empty cups are loaded to get ready for next step to get filled and sealed. The cup silos have a high volume which could be up to 500 capsules. But the amount of empty cups could be loaded varies as the size of the cups might be different based on the products.

- Empty cups from silo dropped into the positions on the lane mold

Here the well stacked empty are dropped separately to positions on the conveyor molds. The specially designed structure ensures the cups are dropped one by one, so that each time in each position, there in only on cup. Thus this will help to make a smooth filling and sealing.

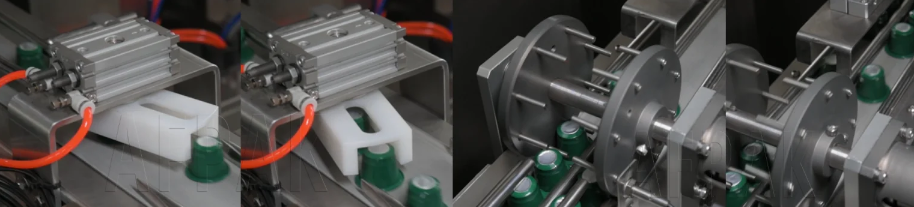

- Cup detection

There are cups detection sensors equipped above the 4 lanes. The principle is if there is no cup on the position of the mold detected, the rest process such as filling and sealing will not be carried out. This improve greatly the high-quality filling and sealing. Without such detection sensors, the powder will be filled into the empty position and will be everywhere, making the machine dirty and increase the difficulty of cleaning.

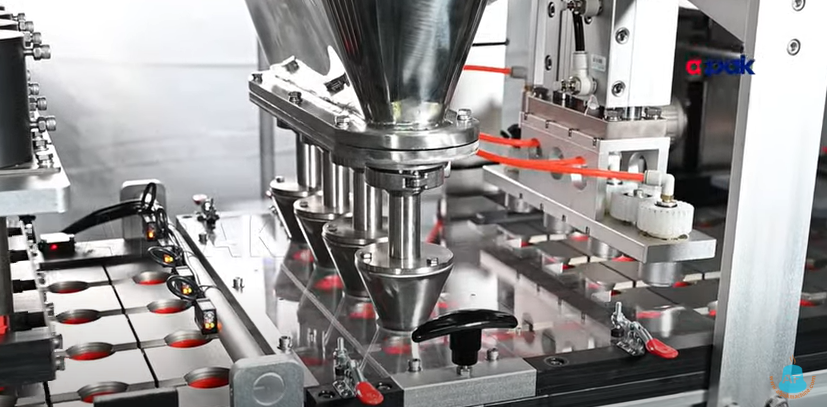

- Powder filled into the cups

There are 4 filling heads connected to the powder or granule silo to delivery the powder and granule into the cups. It is the servo filling system. During the whole process of filling and sealing, the nitrogen are flushed to protect to ensure the freshness of the coffee powder so to extend the shelf life of the cups.

- Edge cleaning

After the cups are filled with coffee powder, there is a edge cleaning system to suck the powder away from the mouth edges of the cups. With powder left on the edges, the film could not be sealed tightly onto the cups. So this step is key to make sure the cups could be sealed completely. Thus it helps to reduce the defective coffee cups products and ensure a longer shelf life of the cups.

- Film put on the cups

This prepared film will be sent to each cups in this step.

- Cups sealed tightly with the film

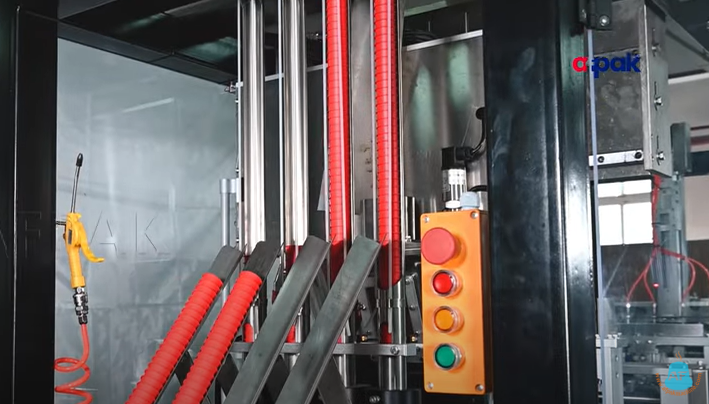

After the cups edge is cleaned and the film is placed on the cup, the sealing process comes. From filling to sealing, nitrogen is flushed to clean the air in the cups. Besides, the yellow tubes on each lane keep sucking the residual powder or granule. Not only could them help clean the cups or pods filled and sealed, but also they would clean the molds and other major parts of the machine for next round filling and sealing.

- Lids sorted out

There is a vibration plate as below to sort out the lids of the cups. This will help with organizing the lids so to correct the position. Then it will deliver the cups to the conveyor on the 4-lane machine. This is optional, as some customer prefer only the film to seal the cups.

- Lids placed on the cups

On the 4-lane machine there are 4 lids sucker. When the 4 columns of the lids delivered to where close to the cups, the 4 lids sucker will suck 4 lids and put it on the sealed cups. There is an enhancing system to firmly fasten the lids on the cups. Here, the cups are completely filled and sealed.

- Cups delivered for packing.

The conveyor will deliver the cups to the AF-B10 box packaging machine for further packing.

- Cups packed into box

The cups could be packed in the form of 5*2, 10*1 or based on customer’s requirement. And the box will be shipped out, ready to be list on the shelf of shops and supermarkets. Take 5*2 format of packing for instance. The cups filled and sealed will be divided into 2 rows and there will be 5 cups in each row by the specially designed system on the boxing packaging machine. There will be a robot hand to grasp the 10 cups and put them into the box.

The main features of AF-HB410 high-end filling and sealing packaging machine

- Automation

AFpak aims at helping customer to maximize the automation during the production so to cut customer’s labor cost. The AF-H4 filling and sealing machine is preferred by the customer to combine it with the AF-B10 box packaging machine to get a turnkey solution from filling and sealing to packing. The automatic production line is hence formed that not only the efficiency is boosted significantly, but also the cost is much lowered. For such big machine, 1 or 2 operators in general would be enough.

- High efficiency

The AF-H4 filling and sealing machine with 4 lanes could complete filling and sealing 4 columns of cups at the same time. The output speed is about 160 to 200 cups per minute. The AF-B10 could possibly pack 20 to 40 boxes each minute. And the efficiency could be further improved if customers select the filling and sealing packaging machine with 6 lanes or 8 lanes. Customization enables the machine to meet various of type of demand from customer.

- Great design

The straight lane design of this AF-HB410 filling and sealing packaging machine is based on the decades years of experience of engineers and also according to suggestion from AFpak’ regular customers. To begin with, this special design has a nice outlook and with a lot of firm glass equipped, it is possible to see though the glass and check how each processing step is carried out. Besides, the straight lane style makes it easier to clean the coffee powder residue. Further, when the AF-HB410 filling and sealing packaging machine was launched, engineers spent a lot of time on cutting the size of the machine smaller to save customer’s space, which is also good for shipping and transportation. The machine size of AF-H4 is 4800mm*1000mm*2300mm and the machine size of AF-B10 is 3500mm*1500mm*1650mm. The weight of them are 1500kg and 1000kg respectively. All the parts and structure are designed by the principle of simplicity. So every part is useful. Furthermore, the well-known brands such as Schneider are used in the machine to ensure s excellent performance. Last but not least, with the straight lane design, the speed of conveyor could be fast to boost the speed of filling and sealing.

- Intelligence adopted

As discussed earlier, sensors are adopted above the lanes of the machine to detect the cups if they are in the position. The sensor heads will sense the cup and feedback to the “brain” of the machine. If there is no cup on the mold, the next few steps including the filling, edge cleaning, sealing, and lids placed would not be carried out. This system would improve the accuracy of filling and reduce the issues of powder scattered everywhere in the machine which might result in the trouble of cleaning. Further, there are lids sensors adopted to ensure a higher quality of sealing. When there are no lids detected, the sealing operation would not be taken place.

- Commonality

Here the commonality of AF-HB410 filling and sealing packaging machine refers to its ability to pack different types of products based on the customers’ demand. Various types of powder and granules such as instant coffee, cocoa powder, tea granules, dry food granules, and other types of powder and granules can be packed by the machine. The position on the molds of the lanes could be changed in terms of size based on the customers’ needs. Highly customization enables AF-HB410 filling and sealing packaging machine to process the production and pack capsules, cups and pods such as Nespresso, Dolce gusto, Lavazza espresso point, K cups and more.

- Simple operation

Though the size of AF-HB410 filling and sealing packaging machine is not small, it only takes 1 or 2 operator to run it. And the operator does not need to be very experienced. Anyone working in the workshop could learn quickly to run the machine. Full guidance and operating instruction will be provided. There will be quick responses from AFpak’s after-sale team for any questions raised. It is one of the best machine in the market for customer who are new to K cups filling and sealing industry.

- High accuracy

The filling processed is carried out at the vertical screw filling part which is driven by the servo motor. The amount of powder or granules are delivered accurately into the cups by the servo motor to make it possible to ensure the almost the same weight of the cups. The accuracy could be reached about 0.2 gram. Besides, the amount of powder or granules to filled into the cups could be adjusted.

- High quality of filling and sealing

From filling to sealing, the nitrogen is flushed, aiming at keeping the freshness and long shelf life of the capsules or cups. There are also edge cleaning process, to prevent any incomplete sealing. Moreover, there is air suction function to suck all the powder out of the molds, so to clean and render the machine clean enough for next round of processing.

- Pre-cut lids or roll film

Both pre-cut lids or roll film could be used on the machine for sealing purpose. Over 1000 pre-cut lids could be stored in the lids silo. There is automation to cut the the film, pick the lids, place the film and seal the film.

More about k cup filling and sealing packaging machines solution, click here