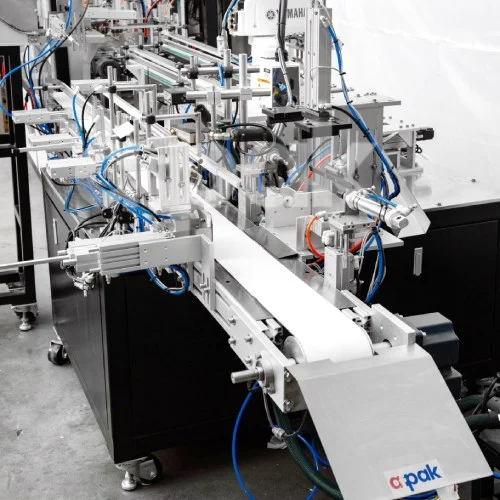

AFPAK의 H 시리즈 K컵 충전 포장 기계는 K컵 충전, 밀봉, 질소 플러싱 및 상자 포장 생산에 이상적입니다. 이 기계는 간단한 변화로 커피 과립, 용해성 분말, 차 과립/잎, 코코아 분말 등을 포장할 수 있습니다. 이 장비는 기능이 풍부하고 작은 면적을 차지하며 안정적인 성능과 우수한 품질을 제공합니다. 이제 우리는 귀하가 선택할 수 있는 2/4/6/8 레인 기계를 보유하고 있으며, 각 레인은 분당 40-50컵을 생산할 수 있습니다.

기능

이 기계는 고품질의 K컵을 생산하기 위한 모든 기능을 갖추고 있습니다.

1- 빈 k 컵 수유

2- 컵 없음 충전 센서 없음

3- 자동 커피 공급 시스템을 갖춘 서보 충전

4- 컵 림 청소 시스템

5- 사전 절단된 뚜껑을 선택하고 배치합니다(롤 필름도 사용 가능).

6- 뚜껑 없음 밀봉 센서 없음

7- 두 번 밀봉 시스템

8- 컨베이어로 출력

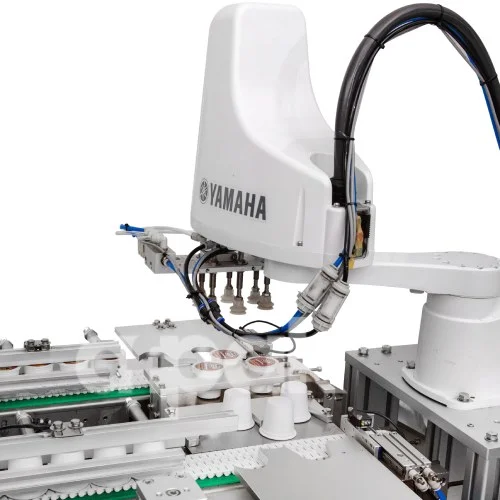

9- 2*3k 컵을 선택하는 로봇 손

10- 빈 상자를 엽니다

11- K컵을 상자에 넣습니다.

12- 씰용 스프레이 접착제

13- 상자 밀봉

14- 최종 상자 출력

우리는 또한 많은 옵션을 가지고 있습니다

O1: 인라인 체중계

O2: 날짜 프린터

O3: 두 번째 캡슐 생산 키트

O4: 밀봉 품질을 확인하기 위한 인라인 카메라

O5: 향료 복용량

O6: 이온화 장치

O7: 원하는 대로 다른 기능을 추가할 수도 있습니다.

이익:

1- 한 사람이면 이 시스템을 운영할 수 있습니다.

2- 하나의 기계로 다양한 제품을 채울 수 있습니다.

3- 하나의 기계는 다른 밀봉 재료를 사용할 수 있습니다

4- 하나의 기계로 다양한 크기의 상자를 포장할 수 있습니다.

더 많은 혜택이 여러분을 기다리고 있습니다.

세부:

| 모델 | HB210 | HB410 |

| 작업 차선 | 2 | 4 |

| 유형 | 선형 유형 | |

| 캡슐 사료 | 수직의 | |

| 드라이브 유형 | 모터 드라이브, 220v 단상/60Hz/50amps | 모터 드라이브, 220-380v 3상 / 60Hz / 60amps |

| 산출 | 80-100 컵 p/분; 6000p/시간 | 분당 160-200컵 시간당 1200컵 |

| 충전 정확도 | +/- 0.2그램 | |

| 기계 중량 | 3300파운드 | 4000파운드 |

| 치수 | 196″x95″100배″ (가로x세로x높이) | 196″x110″100배″ (가로x세로x높이) |

| 전력 소비 | 3.5Kw/h | 5.5Kw/h |

| 질소 소비 | 50-100L/분 0.1Mpa | 100-300L/분 0.1MPa |

| 공기압 소비 | 100-200L/분 0.6-0.8Mpa | 300-400L/분 0.6-0.8Mpa |

| 보증 | 기계 2년, 전기 1년 | |

| 메모 | 또한 선택할 수 있는 6/8개 레인도 있습니다. | |