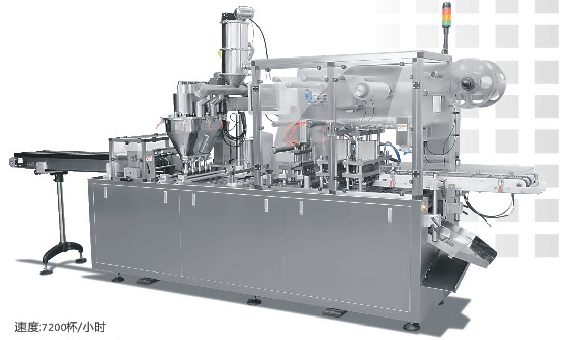

A complete solution of Lavazza point filling machine

Machine details

Breif Introduce of Lavazza point filling machine:

AFPAK Lavazza point filling machine is the latest Version Machine, High speed and high quality, meet EURO machine standard, this model machine is designed specially for Coffee Capsule and Lavazza point and blue Filling and Sealing. Its Material use is better than previous machines; Components use top brand.

*stainless steel frame; Organic glass; one columns mold structure; Fixed castor and mobile pulley.

* Coffee servo screw filling, the filling volume can be adjusted on. Touch screen, no cup no filling

*Automatic vacuum suck lids, No cup no Lids suck. Lids suck fault automatic stop.

*Twice Sealing, Omron temperature controller to adjust the temperature.

Standard Functions of Lavazza point filling machine:

☆Automatic drop empty Nepresso capsule or k cup or lavazza point and lavazza blue

☆Automatic detect whether lavazza point well loaded on the machine by sensor.

☆insert the fitler into lavazza point by hand (Or By Machine).

☆Servo motor to fill coffee while vibrating, weight around 10g ( can be adjust)

☆Auto suck Foil Lids ( Or roll film, cutting and sealing)

☆Auto detect whether the foil lids is ready by Sensor

☆Auto Seal twice

Optional Functions of Lavazza point filling machine:

1. Nitrogen flushing: to extend the shelf life

2. Glass cover: anti-rust

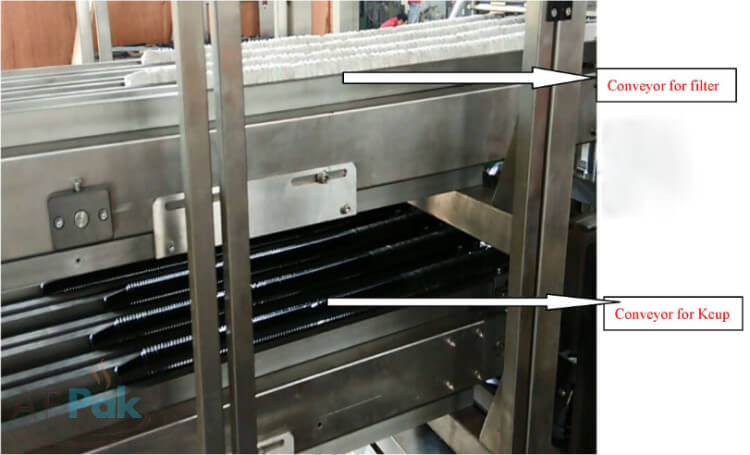

3. Conveyor: help final products output

4. Inkjet printing: print date clearly

(Also can add other functions.)

Applications of Lavazza point filling machine:

AnFPak automatic Lavazza point filling machine has wide applications:

1. filling materials: Powder: Coffee, juice powder, etc.

2. Packing Container: k cup, Nespressp, Lavazza Seires capsules, plastic capsules, small cups,etc.

Lavazza point filling machine

Specifications

| Model | AF-K4/AF-K2 |

| Speed | Over 3600-7200 C/H |

| Working station | 4/2lanes |

| Filling range | 0-20grams |

| Filling accuracy | ±1.5% |

| Voltage | Can be customized |

| Air pressure/gas consumption | ≥0.8Mpa/0.1m² |

| Working Temperature | 5-35°C |

| Relative humidity | ≤85% |

| Machine size | L5000mm*W1000mm* H2600mm |

Detailed pictures

Category: coffee capsule filling sealing