Application of XKL-19 drip coffee packing machine

This XKL-19 drip coffee packing machine is suitable for one-time packaging of small particles inside and outside bags of hanging ear coffee, hanging ear tea, bagged coffee, etc.

Hanging ear coffee is also called: ear hanging coffee, brewed coffee, filter coffee, drip coffee, etc.

Features

1、High compatibility of inner bag packaging materials: non-woven, nylon, corn fiber, and other materials that can be ultrasonically sealed. These materials have good filtration performance and can be widely used in the bag bubble industry.

2、Use a unique sliding volume discharging mechanism: the weight is precise and higher than other volume measuring mechanisms in the current market. Compared with the screw feeding, it will not squeeze the material, which is more versatile and will not damage the structure of coffee because of the heat generated by feeding; compared with the measuring cup feeding weight is more accurate and will not leak powder, servo motor as the power, can achieve fast feeding, to meet the needs of packaging speed.

3、The inner bag adopts ultrasonic sealing and cutting, compared with heat sealing will not produce heat, affecting the quality of coffee; at the same time, the ultrasonic sealing form can achieve a linear cut, saving the internal filling space of the lugs, to achieve a large packaging capacity of 10-20g.

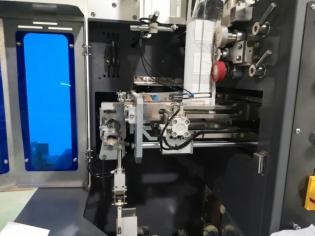

4, using Mitsubishi PLC, multiple Panasonic servo motors as power, a cylinder using SMC brand to control the movement of the machine, 10-inch human-machine interface display, easy to operate; at the same time, according to the specific circumstances of the equipment added a very complete alarm function: material shortage prompt alarm, no material alarm, no film alarm, inner bag empty bag alarm, inner bag color code alarm, inner bag joint alarm, outer bag color code alarm, outer bag empty bag alarm, low air pressure alarm, emergency stop alarm, etc.

5、The outer bag adopts the reciprocating film-pulling structure of a servo motor combined with a color code sensor, which is more stable than the wheel type film pulling bag length, accurate positioning, and beautiful bag shape, and can ensure the stability of equipment operation.

6、Adopt PID adjusting temperature controller, the temperature control is more accurate, to ensure that different films correspond to different temperatures, to achieve the beauty of the outer film packaging.

7、All the parts that can contact the material are made of SUS304 stainless steel to ensure the hygiene and reliability of the products.

8、The additional device of this machine can complete the functions of automatic feeding, date printing, nitrogen flushing, easy tearing mouth, etc..

9、The moving part of this machine adopts closed working environment, which is safe and reliable.

Specifications of XKL-19 Drip coffee packing machine

| Model | XKL-19 |

| Packing speed | 1200-1800 bags/hour |

| Bag type | 3 sides sealing |

| Sealing type | Inner bag sealed with high temperature Outer bag sealed with hot sealing type |

| Voltage supply | Custom to your local type |

| Inner filter bag size | L(70mm-74mm)*W90mm |

| Outer bag size | L120mm*100mm |

| Filling range | 1-20 g |

| Machine dimension | L 1250×W 760×H 2350 (mm) |

| Packaging dimension | 1350*1000*2100 mm |

| Net weight | 660 Kg |

| Gross weight | 760 Kg |

The outer bag composite film base requirements

- Food-grade polyurethane adhesive

- Roll core: paper roll core, the end surface should be treated, not allowed to fall off, roll inner diameter 76-78mm.

- Loose and tight: moderate winding tension, shall not be too tight, leading to product stretching; shall not be too loose, leading to sliding between films when using. When the hand is pushed from outside to inside at the cut surface of both ends of the rolled film, no ripples shall be produced.

- the surface friction coefficient of the composite film: surface friction coefficient (COF) outside ≥ 0.3 inside ≤ 0.25

- low-temperature heat seal means reliable heat seal strength can be obtained at a lower temperature.

- choose heat-sealing materials with good thermal adhesion, otherwise, serious degumming will lead to poor sealing and air leakage.

- Roll film, composite film, composite roll film, aluminum-plastic composite film general diameter control at about 30cm.

- Do anti-static treatment

- Thickness 7-9 micro

The famous XKL-19 Drip coffee packaging machine users