Grow your KCup Packaging business with our Quality Solutions

AFPAK is the leading manufacturer of Kcup filling packaging machines, empty KCups with or without filters, sealing lids, etc.. After ten years of accumulation, we have provided hundreds of coffee companies with high-quality Kcup packaging solutions, allowing them to quickly bring their coffee products to market.

FDA Food Grade

Ultra-Fast Delivery

2023 New KCup Packaging Materials

KCup single serve cups

18 months fresh! 7 Layers (PP-EVOH-PP) oxygen and moist barrier kcups can protect your coffee fresh mostly! Load 7-13 grams coffee granules. also can use for pack other products like cocoa power, milk powder, CBD/THC power, etc...

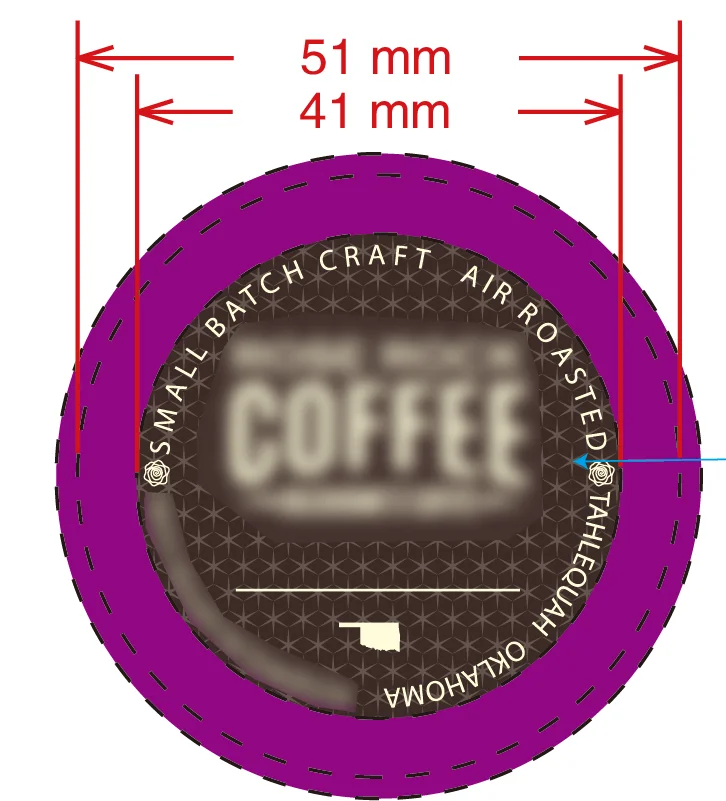

2.0 KCup sealing foil top lid/cover

Special light sensitive ink applied in this new Kcup sealing foils. No OPPS alarm in 2.0 Kcup brewer now! we have purple and orange colors to choose. Small MOQ for customized printing. Send us your designs now

Compostable Biodegradable KCup

Injection-molded compostable biodegradable Kcups are available now! Easy to brewing , enhance the taste of coffee

Small MOQ, Fast Delivery, Quality Guarantee

Small MOQ, Fast Delivery, Quality Guarantee

Send us your designs

If you want to print your designs on kcup lids, kcup package boxes, then please send us your designs. PDF file is OK, AI is better.Our designers will check how many colors and send you the final drawings for confirm.

Confirm everything

Please confirm the quantities of the empty kcups, sealing lids, and boxes, then we will send the Proforma Invoice, you can wire money then

Produce your products

It will spend 2-4 weeks to produce all your products. And we will send the final products or pictures to you.

Done, your kcups, sealing lids, and boxes will be shipped by air or sea.

We will ship out your kcups, sealing lids and boxes by air or sea as requested.

Get a free samples right away

Please leave us your information, we will ship you the free samples ASAP

The Kcup Filling Packaging Machines

A good machine can make you get twice as much done with half the effort

AUTOMATIC MACHINES TO PRODUCE KCUPSRN1S Kcup filling sealing machine

50-70 cpmin, Professional startup solutions, the best selling model

More of RN1S Kcup filling machineKcup Filling Packaging line

100-400 CPMIN, One stop filling, sealing, and packaging solutions. Easy to use and maintain

More of K cup packaging lineSemi auto Kcup filling sealing machine

Lab level filling sealing solutions with 100 cups per hour, best for test the market

More of semi auto k cup filler sealer

Frequently Asked Questions.

All about kcup, sealing lids, and packaging boxes

What is the origin of Kcups?

K-cups or k-cup pods is one of the company’s main products and now is the most popular one in the world compared to other types of coffee cups or pods.

In 1998, Kcup was developed and put into production, aiming to penetrate the office and home market. Since its existence, it has quickly gained market awareness and become the most preferred instant coffee product among the office workers and family with its simplicity and fresh taste. Besides, office coffee machine business have reached another level since the launch of the K-cups, leading to the thriving of the home appliances manufacturing.

The patent for Kcup was expired in 2012. After the patent protection period expires, the patent has been disclosed as a patent that can be used by the public, and the patent will be contributed to the entire society and will no longer be protected by the patent right. As it is open for the world, many factories has seized the opportunity to produce Kcups and gain sales.

According to Wikipedia, “the K-Cup® term is trademarked by Keurig Green Mountain to describe their single-serve brewing capsule. As defined above, you can identify a K-Cup by the foil-lined, ringed design with a plastic cup.”

During the production process, the K-cups will be filled with nitrogen and then tightly filled.

So air, oxygen and dampness or moisture, light could not destroy the flavour of the powder.

Each step of production is subtle and with high accuracy to make sure a production of perfectly filled and sealed K-cups.

Of course, there would be defective items.

But it is rare.

So the freshness of the powder and long shelf life are kept and ensured by the nitrogen flushing and tightly sealing by the filling and sealing machine.

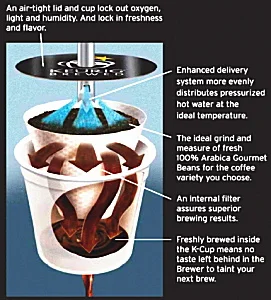

Timing refers to how long to brew the coffee. Specifically, it means how much time for the water to get heated and how much time the hot water run through the coffee powder to get the most flavor out of it.

Temperature means the most proper temperature to brew the coffee powder to deliver the strongest flavor into the into coffee. Keurig suggests that the most suitable temperature for the brewing system to get a great coffee tea, hot chocolate or other drinks is 89 °C which is 192°F. If the temperature is too high, there is possibility the nutrition structure could be destroyed. If the temperature is too low, the flavor and nutrition would not come out with hot water to your cup.

Turbulence could be identified as how strong the flow of hot water runs through the powder so it could carry all the flavor and nutrition to your cup. Slow flow of hot water would carry nothing out of the coffee beans.

The quality of the water simply means the water is just water and it carries no other flavor so not to destroy the origin taste of the coffee. It is the second most important factor to ensure a good quality of hot instant coffee.

Secrets or recipe suggests the how much hot water needed compared to the coffee powder. Too much water will only cause a light taste, meanwhile too less water will only result in thickness of coffee. Those situation will only lead to the unpleasant taste of the hot coffee. The ratio of water to coffee powder depends on personal preference. If you are a espresso fan, less hot water suit you better.

The quality of the coffee powder in side Kcup is dependent on objective and subjective reasons. It is the most important factor as the taste and flavor is generated by the coffee powder. The objective reasons include that how is the quality of the coffee beans which might refers to the place the coffee beans tree grows and what the weather and environment are. The objective also include how the coffee powder is filled into the Kcups which is refers to the quality of the filling and sealing machine. Besides, how the coffee beans are ground into coffee powder could be the other objective reasons. Subjective reasons simply refers to the consumers preference. They all enjoy their best coffee of various types of tastes. There are dazzling brands of Kcups on the market. One should try many different ones to identify the right one for himself or herself.

Other reasons such as the quality of the brewing machine and the quality of the Kcups referring how it is filled and sealed would also affect the quality of the hot coffee.

All in all, a great cup of instant hot coffee is generated by above 6 major reasons. It is hard to define a best hot instant coffee for all and there is no one single standard as everyone has his or her one preference, so you need to try time and time again to find the right brewing machine and right Kcup brand to generate your best instant hot coffee.

What is the difference between coffee pods and Kcups?

Both Kcups and coffee pods are widely used instant coffee products in families and in offices because of their simplicity and time-saving feature. However, those two types of products are quite different in terms of way of being brewed and outlook.

The structure of the coffee pods is much simpler. It is made of round paper and inside there is the coffee or cocoa powder or tea leave. The paper of the coffee pods is considered as the filter.

Compared to the Kcups which could contain 8-13 grams of coffee powder, the coffee pods could contain 7-12 grams, slightly lower. The more complicated structure leads to a higher cost of K-cusps compared to the cost of coffee pods. Thus the price of the Kcups in general is higher.

As the pods are made of the paper, the shelf life is shorter as the filling and sealing of Kcups with nitrogen prevent the air, light or moisture from getting inside to ensure a longer shelf life. This is one the reasons why Kcups are more common and more popular. Besides, there is a richer variety of Kcups as it could store longer.

Secondly, Kcups taste will be further improved. This is related to how to ensure the freshness of the coffee powder in the Kcups. And it takes a lot of more technologies for the Kcup filling and sealing machine to ensure a higher quality of production in terms of filling accuracy, sealing quality and nitrogen flushing and efficiency of the production.

Thirdly, smarter Kcups production. To meet the ever increasing demand of Kcups coffee in the market. The key would be how to improve the efficiency of the machine related to the amount of Kcups produced per hour and the amount of Kcups filled, sealed and packed per hour. Now it might take one worker to control one machine. In the future, one computer might control dozens of machine at the same time.

In brief, the future of Kcup business is bright, the market will grow greatly year by year, and more technologies will be adopted in this industry.

1, PP5 material is food grade, this material is certified by SGS in the United States, non-toxic and harmless to humans.

2, PP5 has outstanding chemical resistance, can be used to make boxes and bottles, etc. PP5 plastic products are made of polypropylene, can be used repeatedly, but also high temperature resistance, is the only plastic can be put into the microwave oven to heat, so you can also use boiling water to scald.

3, PP5 is now the only plastic box can be put into the microwave oven, melting point up to 167 ℃, can be used repeatedly after careful cleaning.

Translated with www.DeepL.com/Translator (free version)

Предметы | Unit | Value |

Материал | PP+EVOH+PE | |

Diameter including edge | мм | 50.80 |

Caliber | мм | 45.72 |

Bottom diameter | мм | 35.61 |

Height | мм | 44.09 |

Емкость | ml | 7-15 |

OTR | cc/cup.day.air | 0.001 |

Average thickness | мм | 0.6 |

According to Emma’s research, any food which is powdered which could be fit into the k-cup could be brewed through warm or hot water to generate a instant cup of beverage. Its time-saving feature and simplicity is incomparable.

And K-cup is no exception with its expired date.

In general, the K-cup of coffee powder could stay fresh for about 18 months if it is not open, sealed tightly in the K-cup pods.

The K-cup is tightly filled and sealed by customized K-cup coffee pods filling and sealing machine to ensure the freshness and a long shelf life.

Statistic also suggests that at least 40% of American families have a Keurig in the house. Each year, there are over 30 billion Kcups are sold and used. Besides, the Covid-19 pandemic has brought a bigger sales as lots of people work at home. Before 2019, averagely people drank 2.45 cups of coffee each day and now this number has grown to 2.77 cups of coffee per day. And the number is still growing. As we could see that the pandemic would not disappear quickly and would exit continuously, still a lot of employee would stay at home for work. That means the sales of Kcups and coffee pods and the brewing machines would be higher.

The reasons behind the over 7% growth, apart from people working from home, are that people have worries about the economy so they become more cautious in the spending while the Kcups or coffee pods would meet their daily coffee consumption demand, and that they are changing the traditional way of buying coffee from local coffee shop to getting a instant coffee by themselves at home. Especially during the pandemic, making instant coffee at home by themselves could prevent them from getting in touch with too many other people.

Kcups adopt recyclable material and are more environment-friendly. It soon gains popularity among those consumers who have a sustainability mindset to protect the environment.

A lof of filling and sealing machine manufacturers such Afpack could provide turnkey solution for filling and sealing the Kcups and using the conveyor to connect the filling and sealing machine to a packing machine so to pack the Kcups automatically.

First, ultra-high stiffness and smoothness is the key advantage.

Looking at the entire packaging market, it can be found that the texture of the outer packaging box of most products is relatively firm and smooth, and the texture is very good to the touch. The requirements for the outer packaging of the product also need to be wear-resistant, waterproof, and anti-collision. White cardboard uses high-quality wood pulp as raw materials. If white cardboard is processed into commodity packaging boxes, it can fully meet the packaging requirements of merchants.

Second, the white cardboard can match various printing colors and materials.

Before the advent of white cardboard, most businesses could only use traditional paper products to print product packaging, and some even used plastic products as product packaging. Regardless of the limitations of the two in other aspects, it will be affected by many factors in terms of design and color printing. However, the use of white cardboard will avoid the existence of this problem. The advantage of white cardboard is that it can be well blended with various pigments and colors.