Кофейные капсулы с одним набором, такие как K-Cups, преобразовали кофейную индустрию, предлагая потребителям удобство и качество в каждом варевах. Если вы владелец кофейного бизнеса-будь то маленький роастер, кафе или крупномасштабный производитель-инвентация в K-Cup Filling Machine Может быть ваш следующий большой шаг. Эти машины оптимизируют процесс заполнения кофе в K-чашки и запечатывают их, обеспечивая консистенцию и эффективность. Но с таким количеством доступных вариантов, как вы выбираете правильный?

В этом руководстве я буду использовать свой многолетний опыт работы в индустрии машин, чтобы помочь вам ориентироваться в мире наполнителей K-Cup. Мы рассмотрим все, от того, что эти машины делают до ключевых факторов, которые вы должны рассмотреть перед покупкой. Ожидайте ответы на общие вопросы, такие как «Сколько стоит машина наполнения K-Cup?» и «В чем разница между ручными и автоматическими моделями?» - все это при включении понимания из реальных поисков пользователей. Давайте погрузимся!

Что такое наполнитель K-Cup и зачем она вам нужна?

Машина для наполнения K-Cup-это специализированное оборудование, предназначенное для автоматизации производства кофейных стручков с одним набором. Он заполняет предварительно сформированные K-чашки кофе (или другими напитками), запечатывает их крышкой и готовит их к упаковке.

Эти машины имеют изменение игры для предприятий, стремящихся производить свои фирменные K-чашки, предлагая такие преимущества, как:

- Контроль над качеством: Вы решаете кофейную смесь, измельчение и размер порции.

- Экономия стоимости: Производство собственного дома может снизить зависимость от сторонних поставщиков.

- Расширение рынка: Предложите уникальные ароматы или фирменные стручки, чтобы выделиться.

Являетесь ли вы стартап-тестированием вод или устоявшейся компанией, масштабируясь, наполнитель K-Cup может сэкономить время, обеспечить согласованность и удовлетворить растущий спрос. Но с различными типами и доступными функциями очень важно понимать ваши варианты.

Типы машин для наполнения K-Cup: ручное, полуавтоматическое и автоматическое

Один из первых вопросов, которые задают покупателям: «В чем разница между ручным и автоматическим наполнительным машинами K-Cup?» Вот разрушение трех основных типов:

Мануальные машины для наполнения K-Cup

- Обзор: Эти машины требуют, чтобы операторы обрабатывали большинство шагов - заполнение чашек, наполнение кофе и герметичные крышки. Они идеально подходят для мелкого производства или предприятий, только начинающих.

- Плюс: Доступный (начиная с нескольких сотен долларов), компактный и прост в использовании для низких объемов.

- Минусы: Трудоемкая и ограниченная мощность (например, AF-BZD95 уплотнения до 600 чашек в час с квалифицированной работой).

- Лучше всего для: Стартапы или небольшие кофейни, производящие партии по 100–500 K-чашкам в день.

Полуавтоматические машины для наполнения K-Cup

- Обзор: Они набирают баланс, автоматизируют части процесса (например, наполнение или герметизация), в то же время нуждаясь в некотором ручном вводе.

- Плюс: Быстрее, чем ручные машины, по умеренной цене и подходят для растущих предприятий.

- Минусы: По -прежнему требует участия оператора, ограничение масштабируемости.

- Лучше всего для: Жорры среднего размера, производящие 500–2000 K-чашек в день.

Полностью автоматические машины для наполнения K-Cup

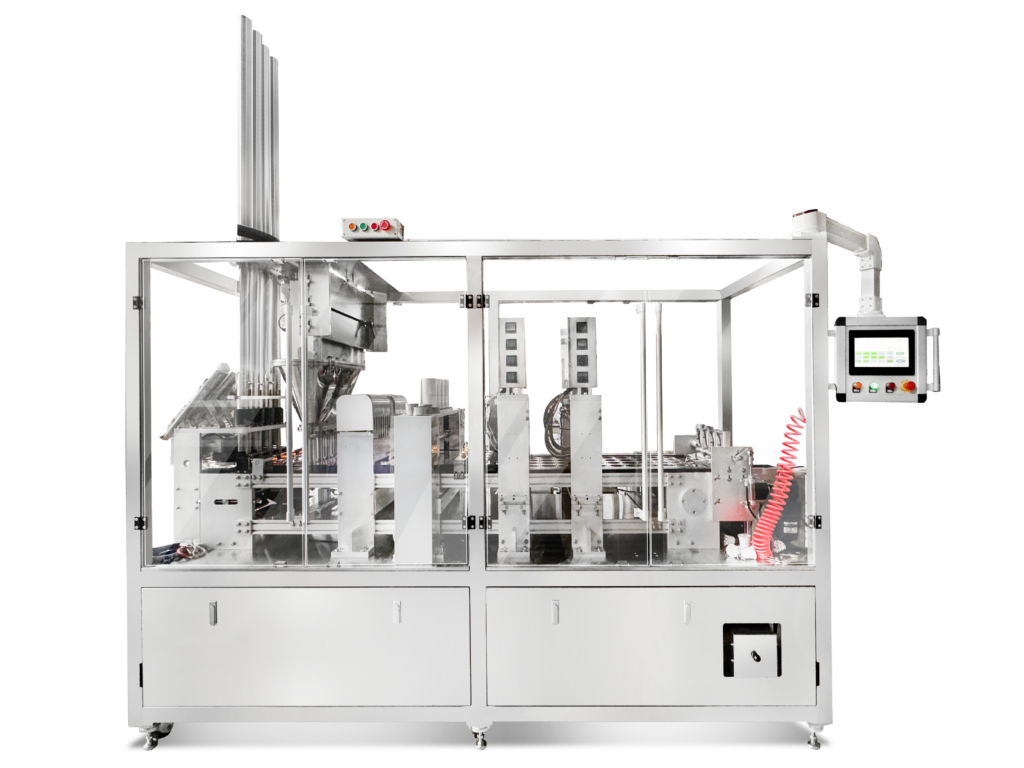

- Обзор: Они обрабатывают все - кормление, наполнение, запечатание и выброс - с минимальным вмешательством человека. Подумайте о высокотехнологичных решениях, таких как AF-RN1S AFPAK, которые выпускают до 3000 K-чай в час.

- Плюс: Высокая эффективность, постоянная мощность и расширенные функции, такие как промывка азота.

- Минусы: Более высокая стоимость (часто 20 000 долларов+) и больший след.

- Лучше всего для: Крупные производители или предприятия планируют быстрый рост.

Ключевой вынос: Сопоставьте тип машины с вашими производственными потребностями и бюджетом. Начиная с малого? Пойти в руководство. Масштабирование? Рассмотрим полуавтоматический или автоматический.

Ключевые функции для поиска в машине для наполнения K-Cup

При исследовании «Что я должен искать в машине для наполнения K-Cup?» Несколько функций выделяются как необходимые. Вот что нужно расставить приоритеты:

- Производственная мощность: Сколько K-чашек вам нужно ежедневно? Вручные машины обрабатывают небольшие пробежки, в то время как автоматические борьбы с тысячами в час (например, AFPAK YM40 предлагает 1500-2400 чашек/час).

- Точность заполнения: Точность вопросов для консистенции вкуса. Ищите машины с сервомоторными шнеками, имеющими точность ± 0,2 грамма.

- Технология уплотнения: Сильная, герметичная печать сохраняет свежесть. Тепло и герметизация давления с регулируемыми настройками идеально.

- Простота использования и очистка: Интуитивно понятные элементы управления (например, сенсорные экраны) и простые в очистке конструкции уменьшают время простоя-необходимо для занятых операций.

- Промывка азотом: Эта особенность уменьшает кислород в чашке, продлевая срок годности и поддерживая вкус. Это премиальное дополнение, которое стоит рассмотреть.

- Кастомизация: Нужны фирменные крышки или разные размеры чашек? Машины, подобные машинам от AFPAK, предлагают адаптированные варианты.

Для чаевого: Проверьте эти функции против ваших целей. Если качество и срок годности являются приоритетами, точностью заполнения, технологии промывки азота и уплотнения должны превзойти ваш список.

Конкретные функции и дополнительные функции полностью автоматических машин для наполнения K-Cup

Полностью автоматические машины для наполнения K-Cup разработаны для оптимизации производственного процесса с минимальным вмешательством человека, обеспечивая высокую эффективность, последовательность и качество. Эти машины оснащены важными стандартными функциями для крупномасштабного производства, а также дополнительные функции, которые позволяют предприятиям настраивать их в соответствии с конкретными потребностями. Ниже мы подробно описываем как основные функции, так и дополнительные усовершенствования.

Стандартные функции полностью автоматических машин для наполнения K-Cup

Эти машины интегрируют набор ключевых функций, чтобы полностью автоматизировать производство K-CUP. Вот что они обычно включают:

- Автоматическое кормление чашки: Пустые K-чашки автоматически загружаются в производственную линию из бункера или системы кормления, обеспечивая устойчивую подачу без ручных усилий.

- Точная начинка: Сервовированные шнеки или передовые системы измерения заполняют каждую K-Cup кофе (или другими продуктами, такими как чай или какао) до точности ± 0,2 грамма, гарантируя однородность.

- Смущение и уборка: После заполнения, машина подрывает содержимое для последовательной плотности и очищает обод чашки, чтобы удалить остатки, готовя его к герметике.

- Размещение и герметичность: Предварительно вырезанные крышки (или крышки, вырезанные из рулона) автоматически помещаются и запечатаны на K-чашки с использованием тепла и давления, обеспечивая герметичное закрытие для сохранения свежести.

- Промывка азотом: Стандартная особенность во многих моделях, это снижает уровень кислорода внутри K-Cup до ниже 2%, продлевая срок годности и поддерживая целостность вкуса.

- Датчики управления качеством: Встроенные датчики мониторинг на наличие дефектов, таких как отсутствующие чашки, смещенные крышки или ошибки заполнения, автоматически отклоняя неисправные подразделения в соответствии с стандартами качества.

- Автоматический разряд: Завершенные K-чашки выброшены с машины автоматически, готовы к упаковке или дальнейшей обработке.

- Интерфейс сенсорного экрана: Интуитивно понятный сенсорный экран позволяет операторам контролировать производительность, регулировать настройки (например, вес заполнения или температура уплотнения) и решать проблемы в режиме реального времени.

Эти основные функции делают полностью автоматические машины для наполнения K-Cup надежным решением для предприятий, стремящихся эффективно производить K-Cups в масштабе.

Дополнительные функции для улучшенной настройки

Помимо стандартных возможностей, производители предлагают дополнительные функции для удовлетворения разнообразных производственных требований. Вот некоторые общие улучшения:

- Вставка фильтрации: Автоматически вставляют фильтры перед заполнением, идеально подходит для чая с лишним листьев или специальных кофейных смесей, требующих фильтрации.

- Многоформатная совместимость: Позволяет машине создавать различные типы стручков с одной серию (например, K-Cups и Nespresso-совместимые капсулы) с быстрыми деталями, уменьшая время простоя.

- Вкусовое дополнение: Добавляет систему для введения точного количества жидкого ароматизатора во время начинки, идеально подходит для ароматизированного кофе или уникальных линий продуктов.

- Встроенная система взвешивания: Увеличение контроля качества с помощью проверки веса в реальном времени для каждой K-CUP, дополняя стандартную точность заполнения.

- Руловая резка и герметизация: Использует систему рулона для разрезания и герметизации крышек на месте, сокращения затрат на материал и отходов по сравнению с крышками предварительно обрезания, особенно в прогонах с большим объемом.

- Интеграция генератора азота: Пары с промывками азота путем интеграции встроенного генератора азота, предлагая экономически эффективную, эффективную предложение.

- Удаленный мониторинг и управление: Обеспечивает удаленный доступ к производственным данным и производительности машины с помощью мобильных устройств или компьютеров, улучшая надзор.

- Автоматическая коробка и упаковка: Добавляет модули, чтобы автоматически упаковать готовые k-cups в коробки или другие форматы, минимизируя ручной труд.

- УФ -стерилизация: Включает УФ -системы для стерилизации чашек перед заполнением, соответствует высоким стандартам гигиены для чувствительных продуктов.

Эти дополнительные функции позволяют предприятиям адаптировать машину к конкретным производственным целям, повышая универсальность и эффективность.

Почему эти функции имеют значение

Комбинация стандартных и дополнительных функций предлагает значительные преимущества:

- Эффективность: Функции автоматизации, такие как кормление CUP и автоматическое увеличение производства и масштабируемость.

- Качество: Датчики и системы взвешивания обеспечивают постоянную, без дефектов.

- Кастомизация: Такие варианты, как добавление вкуса и многоформатная совместимость, позволяют разнообразным продуктам.

- Экономия стоимости: Такие функции, как герметизация рулона и генераторы азота, снижают долгосрочные эксплуатационные расходы.

Сколько стоит машина наполнения K-Cup?

Лучший запрос Google: «Сколько стоит машина наполнения K-Cup?» Цены сильно различаются:

- Ручные машины: Начните с 800–1000 долларов. Стартовый комплект AFPAK, в том числе 1000 чашек, стоит менее 2000 долларов.

- Полуавтоматические машины: Варьируется от 1000 до 3000 долларов, в зависимости от функций.

- Полностью автоматические машины: Начнется с 15 000 долл. США и может превышать 50 000 долл. США для моделей высокого класса, таких как AFPAK.

Скрытые затраты на рассмотрение

- Обслуживание: Регулярное обслуживание и детали (например, уплотнения или шнеки) складываются.

- Обучение: Операторам может потребоваться обучение, особенно для автоматических систем.

- Энергия: Большие машины потребляют больше мощности, влияя на счета за коммунальные услуги.

- Финансирование: Многие поставщики (например, CoffeeTec) предлагают планы оплаты, чтобы облегчить авансовый хит.

Совет составления бюджета: Рассчитайте общую стоимость владения - цена покупки плюс текущие расходы - чтобы избежать сюрпризов.

Послепродажная поддержка и гарантия: почему это важно

В мире машин поддержка может сделать или сломать ваш опыт. Поломка машины без помощи в поле зрения - это кошмар. Вот что проверить:

- Техническая поддержка: Ищите 24/7 помощь, помощь в установке и обучение. Afpak превосходит здесь с круглосуточной онлайн-поддержкой.

- Гарантия: Стандарт - один год на деталях, но некоторые (например, Coffeetec) предлагают расширения. Уточнить детали покрытия - включает ли это труд?

- Доступность деталей: Быстрый доступ к запчастям минимизирует время простоя. Спросите о времени доставки.

- Местный сервис: Если возможно, выберите поставщика с соседними техниками.

Промышленность понимания: Я видел, как предприятия процветают с надежной поддержкой и борьбой без него. Распределите приоритеты производителей с твердой репутацией.

Обеспечение соответствия стандартам безопасности

Поскольку K-чашки являются пищевыми продуктами, безопасность не подлежит обсуждению. Ваша машина должна соответствовать стандартам, таким как:

- Сертификация CE: Обычно в Европе обеспечивает безопасность и качество.

- Стандарты ISO: Сигнализирует последовательные производственные практики.

- Соблюдение FDA: Критическое для рынков США, обеспечение безопасных пищевых материалов.

Машины известных брендов, таких как AFPAK, часто имеют сертификаты CE и ISO. Конструкция из нержавеющей стали и гигиенический дизайн еще больше повышают соответствие требованиям.

Быстрая проверка: Попросите поставщиков предоставить сертификаты — это ваша гарантия качества.

Настройка и совместимость: удовлетворение ваших уникальных потребностей

«Существуют ли машины для наполнения стаканчиков K-образной формы, которые могут обрабатывать стаканчики разных размеров?» Да, и вот как:

- Совместимость чашек: убедитесь, что машина поддерживает ваши чашки K-Cup — стандартные, K-shot или другие. Некоторые поддерживают несколько форматов.

- Варианты брендинга: Хотите, чтобы ваш логотип был на крышках? Такие компании, как AFPAK, предлагают настройку.

- Интеграция: Нужно ли, чтобы оно работало с существующим оборудованием? Ищите адаптируемые конструкции (машины AFPAK легко интегрируются).

Экспертное примечание: Кастомизация может выделить ваш продукт — не упускайте ее из виду, если брендинг имеет значение.

Как выбрать правильную машину для наполнения K-Cup для вашего бизнеса

Вот пошаговое руководство, позволяющее ответить на вопрос: «Как выбрать лучшую машину для наполнения стаканчиков K?»

- Определите производственные цели: Сколько K-чашек в день? Небольшие тиражи (100–500) подходят для ручных машин; большие объемы (2000+) требуют автоматического.

- Установите бюджет: Включите затраты на покупку и эксплуатацию. Финансирование может помочь с более дорогими моделями.

- Измерение пространства: Ручные машины подходят для труднодоступных мест; автоматическим нужно место (размеры проверьте в Интернете).

- План роста: Масштабируемая машина предотвращает будущие обновления. Полуавтомат – это золотая середина.

- Поддержка исследований: Прочтите обзоры или попросите рекомендации. Хороший сервис стоит своих денег.

- Проверка соответствия: Убедитесь, что сертификаты соответствуют нормам вашего рынка.

- Проверьте это: Если возможно, посмотрите его в действии с помощью демо-версии или пробной версии.

Пример реального мира: Мой клиент начал с ручной машины, которую в течение года перевели на полуавтоматическую, а теперь использует автоматическую линию — и все потому, что они планировали заранее.

Последние мысли: внесение правильных инвестиций

Покупка K-Cup Filling Machine Это важное решение, но оно может поднять ваш кофейный бизнес на новый уровень. Независимо от того, используете ли вы модель с ручным управлением или погружаетесь в крупносерийное производство с помощью автоматической системы, главное — подобрать машину в соответствии с вашими потребностями, бюджетом и планами роста.

За годы работы в машиностроительной отрасли я понял, что лучший выбор сочетает в себе стоимость, качество и поддержку. Тщательно исследуйте, задавайте поставщикам сложные вопросы и не экономьте на безопасности и обслуживании. Используя подходящую машину для розлива в стаканы K, вы будете производить первоклассные капсулы, которые заставят клиентов заваривать пиво и будут возвращаться за новыми порциями.

Готовы начать делать покупки? Используйте это руководство в качестве дорожной карты, и вы найдете идеальную машину, которая воплотит в жизнь ваши мечты о кофе.