Feeling lost in the world of coffee capsule production? Wondering where to even begin? You're not alone; it's a common issue.

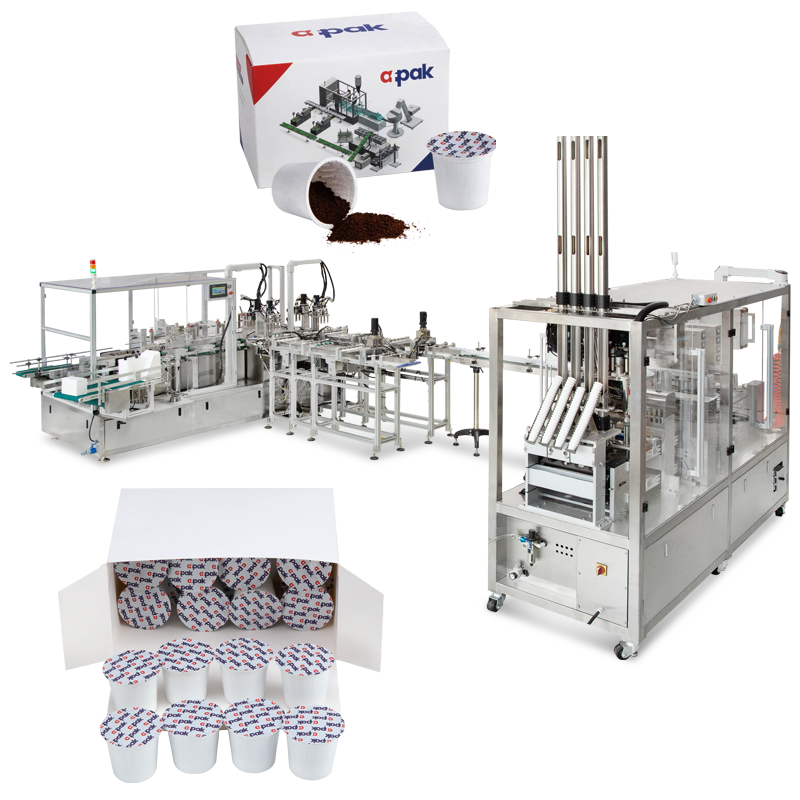

A K-cup filling machine is a specialized piece of equipment designed to automatically fill and seal single-serve coffee capsules, specifically those compatible with Keurig brewers. These machines can handle the entire process, from dispensing the coffee grounds to sealing the lid, and they are standard for 8-13g coffee, ensuring consistent quality and freshness.

K-cup filling machines simplify the coffee capsule production. But they are complex pieces of equipment. Lets break it down.

what is the k cup filling machine used for?

New to K-cup production and confused about what these machines actually do? It seems complex, but it's important to understand the core function.

K-cup filling machines are primarily used for producing coffee capsules for Keurig machines. They handle filling, sealing, and nitrogen flushing. You can also add features like weighing and coding.

The primary use is, of course, coffee. But they're more versatile than you might think. K-cup filling machines aren't just for coffee. You can also use them for milk powder, tea powder, matcha, and other powdered materials. You can even modify the filling structure to handle granular products. This flexibility is crucial. It opens up possibilities beyond coffee. Think about different flavors, or even health-focused products. Consider ease of cleaning, too. You don't want coffee residue in your tea capsules.

| Filling Material | K-cup Machine Adaptability | Considerations |

|---|---|---|

| Coffee Powder | Standard | Grind size, density |

| Milk Powder | Adaptable | Flow properties, stickiness |

| Tea Powder | Adaptable | Leaf size, density |

| Matcha Powder | Adaptable | Fineness, clumping |

| Granular Products | Requires Modification | Particle size, flow |

what's the working principle of the Kcup fillng machines?

Struggling to visualize how a K-cup filling machine actually works? The process can seem like magic, but it's all about precise mechanics.

The basic working principle involves several automated steps: cup dispensing, filling with the product (usually coffee), tamping (compressing) the product, sealing the top with a foil lid, and discharging the finished K-cup. It's a smooth and efficient workflow.

Think of it like an assembly line. First, empty K-cups are loaded. They move to the filling station. A precise amount of coffee (or other product) is dispensed. The coffee is then tamped down. This ensures even extraction. A foil lid is placed on top. The lid is sealed, creating an airtight container. Finally, the finished K-cup is ejected. Many machines also flush the K-cup with nitrogen. This removes oxygen. It keeps the product fresh for longer. The entire process is controlled by a PLC (Programmable Logic Controller). This ensures accuracy and consistency. Sensors monitor each step.

| Step | Action | Key Component | Purpose |

|---|---|---|---|

| Cup Dispensing | Loads empty K-cups into the machine | Denester | Starts the production process |

| Filling | Dispenses the product into the K-cup | Servo motor controlled Auger Filler | Accurate measurement of product |

| Tamping | Compresses the product inside the K-cup | Tamping Head | Ensures even extraction during brewing |

| Sealing | Applies and seals a foil lid to the K-cup | Sealing Head | Creates an airtight seal, preserves freshness |

| Nitrogen Flush | Injects nitrogen gas into the K-cup | Nitrogen Flushing System | Removes oxygen, extends shelf life |

| Discharge | Ejects the finished K-cup from the machine | Output Conveyor | Completes the production cycle |

what is the prices range for K-cup filling machines?

Budget concerns holding you back from investing in a K-cup filling machine? Price is a major factor for any business. Let's look at the options.

K-cup filling machine prices vary widely, from around $10,000 to over $500,000. This depends on production capacity, quality, features, and the level of automation. For small-scale testing, semi-automatic options exist in the $1,000-$2,000 range.

There's a machine for every budget. Starting small? A semi-automatic machine might be perfect. These are less expensive. They require more manual labor. But they're great for testing or low-volume production. Ready to scale up? Automatic machines are the way to go. These are faster. They require less labor. But they cost more upfront. The price also depends on features. Do you need nitrogen flushing? Weighing? Automatic lid placement? Each feature adds to the cost. Consider your long-term goals. Investing in a higher-capacity machine might be worth it. Even if you don't need it right away. It gives you room to grow.

| Machine Type | Price Range (USD) | Production Capacity (Cups/Hour) | Features |

|---|---|---|---|

| Semi-Automatic | $1,000 - $2,000 | Low (Manual) | Basic filling and sealing |

| Entry-Level | $10,000 - $50,000 | 500 - 1,000 | Automated one lane filling, sealing |

| Mid-Range | $50,000 - $100,000 | 2,000 - 12,000 | Multi-head 2/4 lanes fillers, automated sealing |

| High-End | $100,000+ | 12,000+ | 6+ lanes Advanced automation, high throughput |

What other machines to work with Kcup filling machines?

Thinking a K-cup filling machine is all you need? It's the core, but other equipment can boost efficiency.

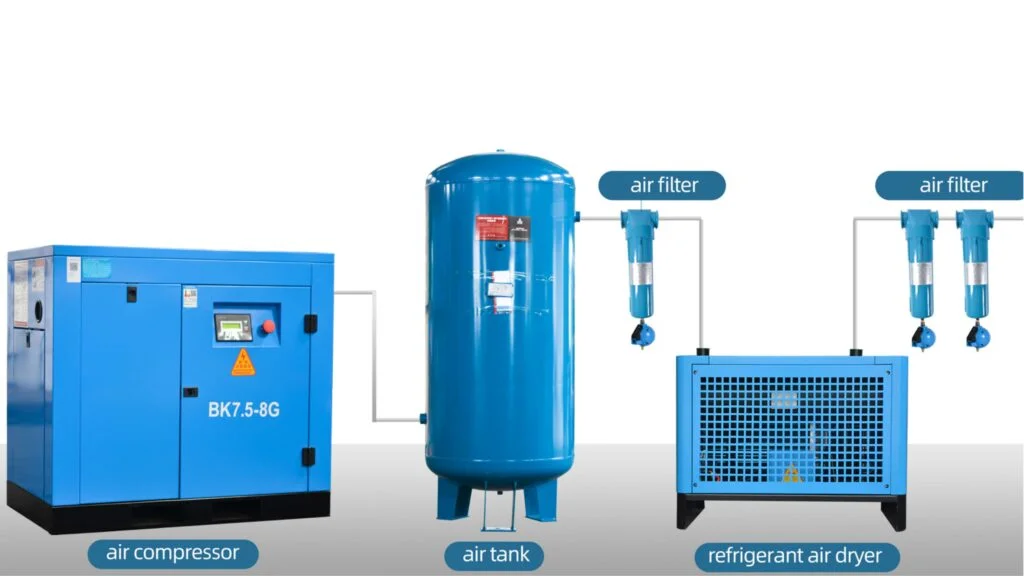

Besides the filling machine itself, you'll typically need an air compressor and a nitrogen generator. For higher production, consider a K-Cup cartoning machine to automate packaging.

The filling machine is the heart of the operation. But it doesn't work alone. An air compressor is essential. It powers many of the machine's functions. Pneumatic systems use compressed air. A nitrogen generator is also crucial. It provides the nitrogen for flushing. This keeps the product fresh. For larger operations, consider additional equipment. A cartoning machine automates boxing. It packs filled K-Cups into cartons. This saves time and labor. A checkweigher ensures each K-Cup has the correct weight. This maintains quality control. A printer can add date codes or other information. This is important for traceability. Think about your entire process. From start to finish. Automate as much as possible. This increases efficiency. It reduces costs in the long run.

| Supporting Equipment | Function | Benefit |

|---|---|---|

| Air Compressor | Provides compressed air for machine operation | Powers pneumatic systems |

| Nitrogen Generator | Supplies nitrogen gas | Preserves freshness, extends shelf life |

| K-Cup Cartoning Machine | Automatically packs K-Cups into cartons | Increases packaging efficiency, reduces labor |

| Checkweigher | Verifies the weight of each K-Cup | Ensures consistent product quality |

| Printer | Prints date codes, batch numbers, etc. | Provides traceability and product information |

Conclusion

K-cup filling machines are essential for efficient coffee capsule production. By understanding the different components, you can choose the right machine for your business.