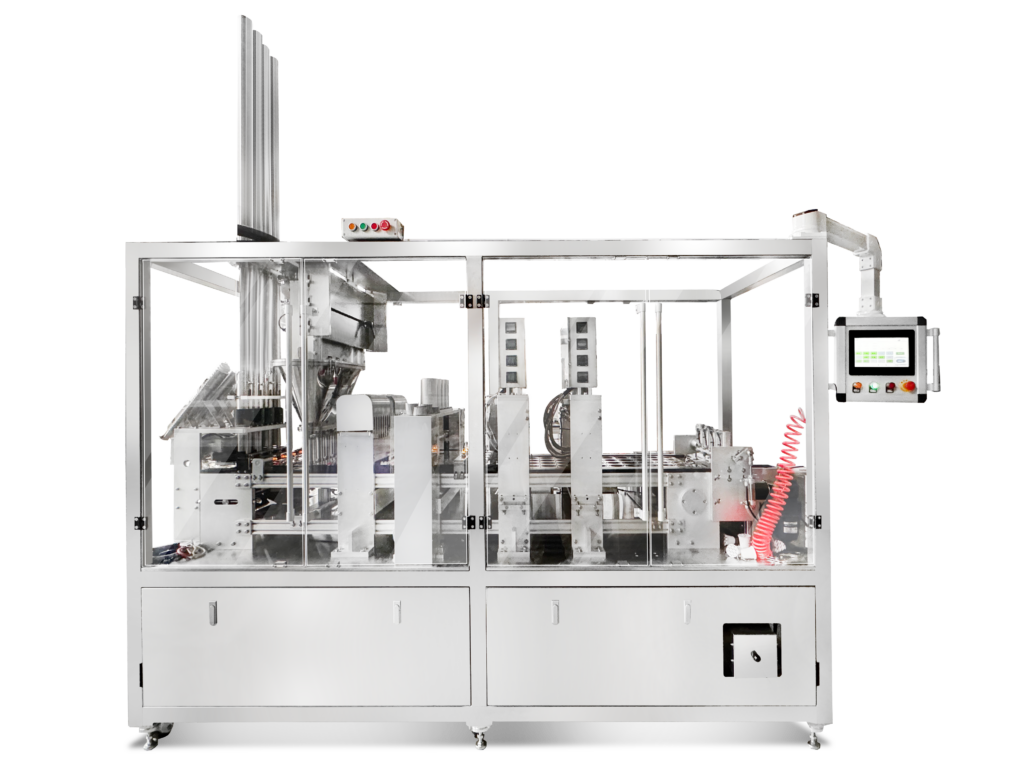

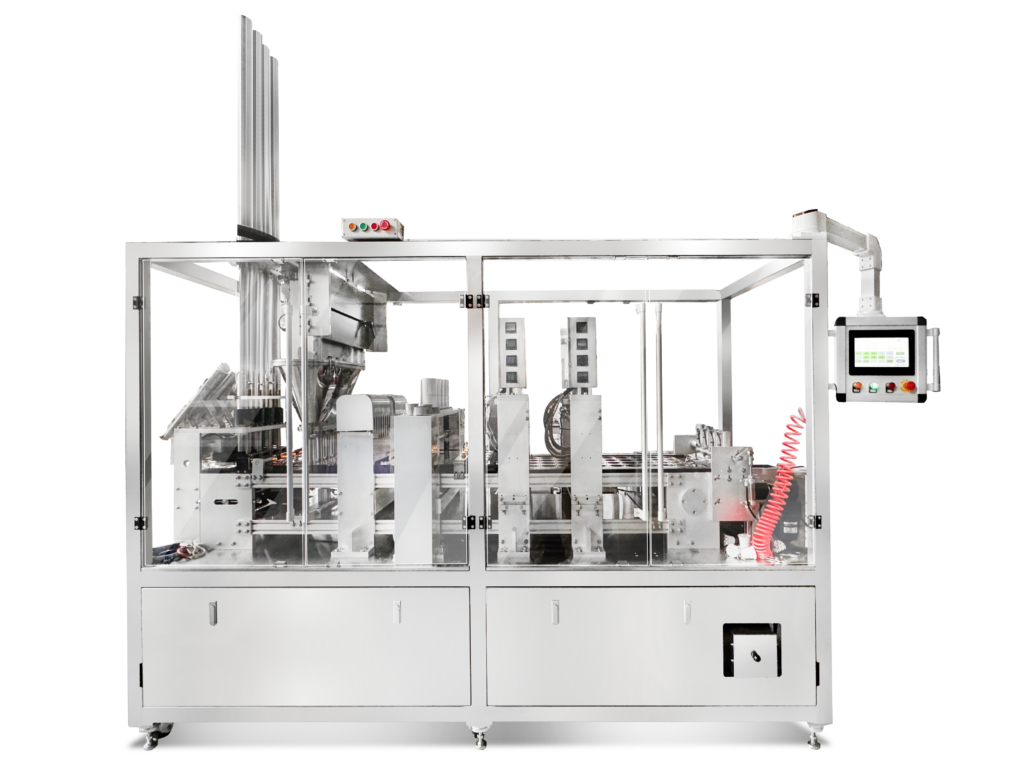

The NESPRESSO capsule cartoning machine is a piece of equipment specifically designed to pack NESPRESSO-compatible coffee capsules into boxes.

Nespresso cartoning machine sometimes named Nespresso capsule packing machine or Nespresso packaging machine. It has the characteristics of high efficiency, accuracy, and stability, and can be customized to meet the cartoning needs of different specifications and requirements.

This machine is suitable for packaging 10*1 long coffee capsule sleeve boxes. We can also design equipment to package other box types such as 5*2, 4*2+2, etc.

The working principle of the NESPRESSO cartoning machine is:

First, put the empty box into the box warehouse, then the conveyor belt sorts the coffee cups and grabs them into the cup warehouse. The sensor detects the position of the coffee capsule cup, and then the robot arm grabs the box and sends it to the box. area. In the boxing area, there is a push device for NESPRESSO coffee capsules to push the capsules into the box. When the box is full, the hot melt glue device sprays hot melt glue and attaches the cover to the box. This completes the entire boxing process

This machine is mature and stable, well-made, high-efficiency, and excellent in performance. It is your ideal production equipment

Benefits of having AFPAK-B10H Nespresso capsule cartoning machine

Improve production efficiency: NESPRESSO cartoning machine is an automated equipment that can package coffee capsules in an efficient manner. It can quickly complete a large number of packaging tasks, reduce labor costs, and improve production efficiency.

Guarantee product quality: The cartoning machine is equipped with a quality control system to ensure that each coffee capsule is accurately packaged to avoid any quality issues. This helps maintain product consistency and quality.

Reduce human errors: Manual packaging may introduce human errors, such as weak packaging or irregular packaging. Automated cartoning machines can reduce these errors and ensure that every product meets standards.

Enhance brand image: Good packaging can attract customers’ attention, improve the quality of the product, and help establish the brand image.

Reduce waste: Automated cartoning machines can effectively manage packaging materials, reduce waste, and improve resource utilization efficiency, helping to reduce packaging costs.

Increased production volume: The cartoning machine is able to process a large number of orders in a shorter period of time, thereby increasing the production volume of the product and meeting the market demand.

In general, owning a NESPRESSO cartoning machine can improve production efficiency, quality and customization capabilities, reduce costs and resource waste, and at the same time help improve the quality of product packaging, maintain brand image, and attract more consumers. This is a beneficial investment for your coffee production and packaging business.

Functions:

Coffee capsule feeding system

We only need your coffee capsule cups to be supplied in one line, and our conveying system will automatically split into two lines and flip them over

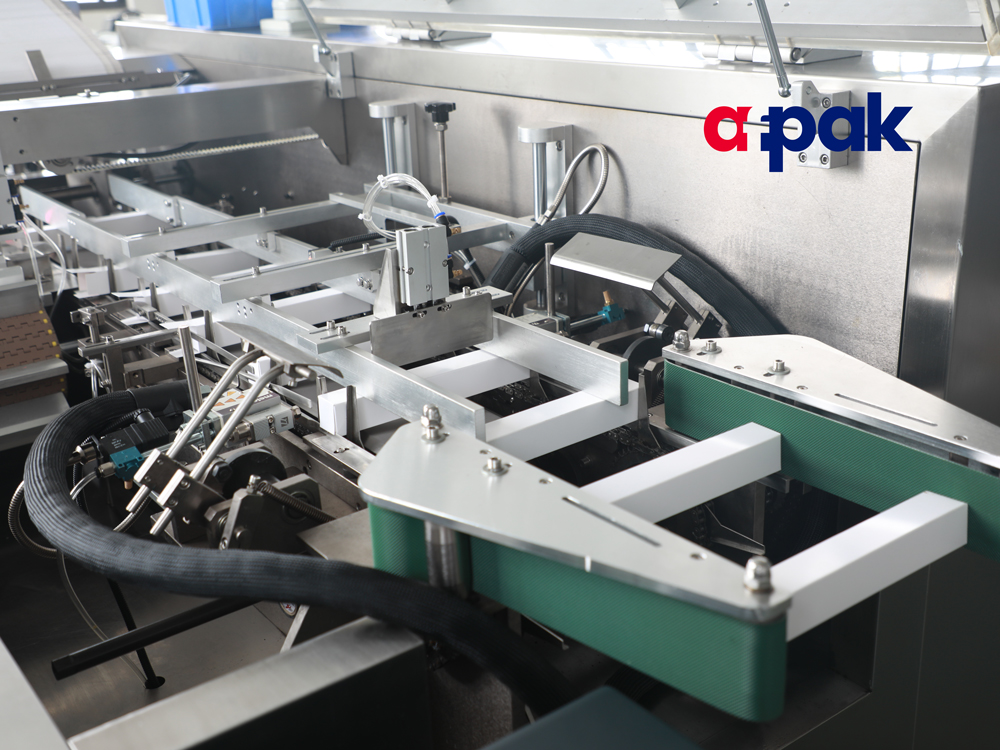

Coffee capsules pick and place

Auto pick and place 5*2 capsules and place into the box tray

The conveying system will auto-separate capsules to stand 5*2 lanes

This system can guarantee up to 30 times per min pick and place speed

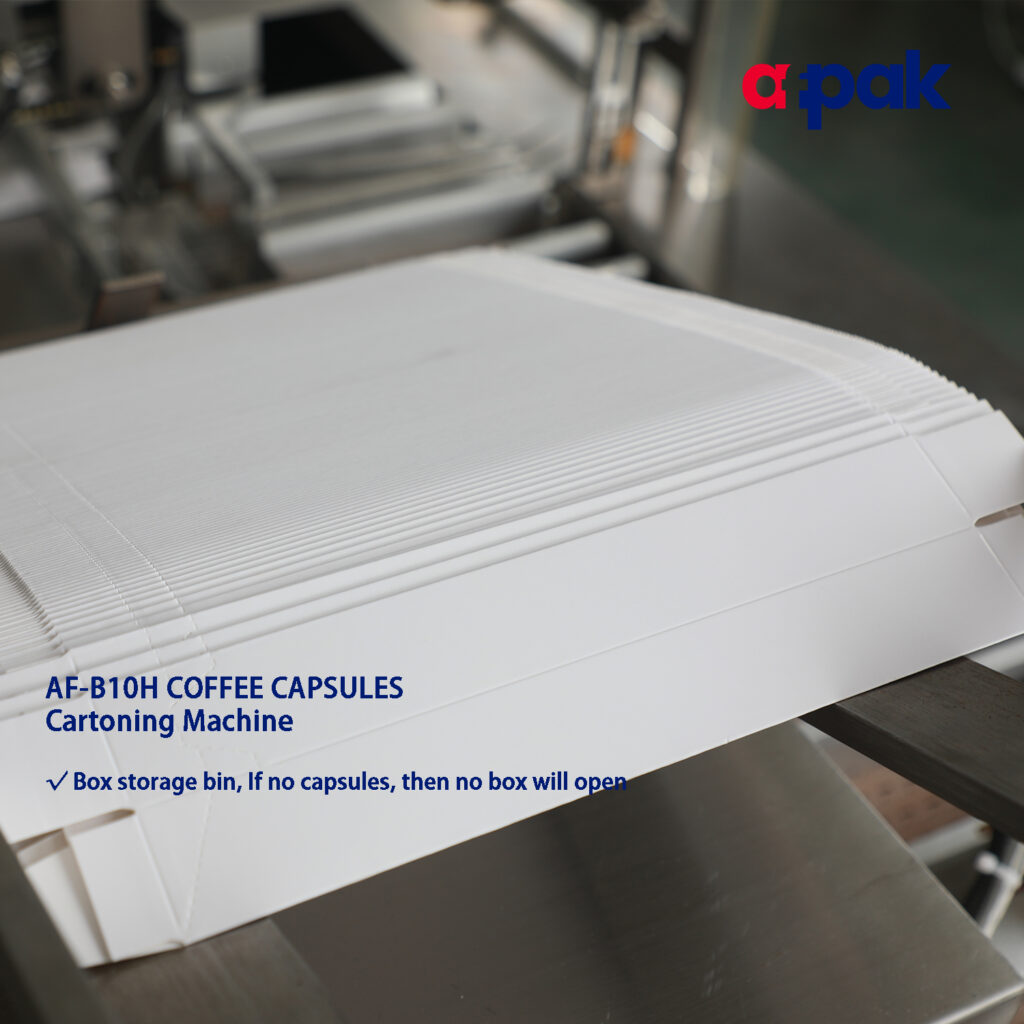

Box storage bin

Large box compartment provides more storage space for empty boxes

In addition, there is a sensor switch for opening the empty box. If there is no cup in the cup compartment, the box will not be opened.

Push coffee capsules into the box

Auto push all capsules into the box by servo motor

Auto close the box with the glue seal

Auto close both ends of the box and sealed with hot melt glue

You can also use the foldable boxes without glue to seal

Configure Hot Melt Glue Machine

We have equipped you with inkjet printers from internationally renowned brands to ensure your smooth production.

If you have specific brand requirements, you can also tell us

English/Chinese Control System

Our equipment uses electrical components from major international brands, such as Siemens, Schneider, Omron, etc., to ensure production safety as much as possible.

In addition, our system language can also be set to your local language to help your operating functions better understand and use the device

Our Nespresso capsule cartoning machine has more functions, welcome to contact us for a more detailed quotation

Specifications

| Model | AF-B10H |

| Paper box’s smallest size | 110×60×15mm |

| Paper box’s largest size | 280×90×38mm |

| Production speed | 8-30 boxes /min |

| Power supply | 220V;50/60HZ |

| Motor horsepower | 2.5 kW |

| Compress air consumption | 90 PSI, 15CFM |

| Main Machine measurement | 4150*3772*1933 mm |

| Machine weight | 1000Kg |

Recommend Nespresso filling sealing machine to work with B10H Nespresso capsule cartoning machine

RN1S model

B10H Nespresso capsule cartoning machine can work 3-4 sets Of RN1S model nespresso coffe capsule filling sealing machines

H2/4 model

B10H Nespresso capsule cartoning machine can work 1-2 sets of h3/4 model nespresso coffe capsule filling sealing machines